Evolving Change Control To Global Enterprise Change Management

By Ashley Watkins, Industry Solution Manager, Sparta Systems

The Fundamentals Of Change Control

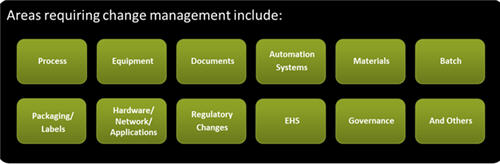

Change control is a well-known GMP requirement focused on controlled management of change to prevent unintended consequences. In the pharma world, change control ensures that the safety, quality, purity, and potency of pharmaceutical products and biologics are not compromised due to any changes in processes or production. Pharmaceutical companies, API and raw material suppliers, contract manufacturers, and other companies across the pharma ecosystem must have systems in place to evaluate change, track change, and apply adequate change control. All changes must be traceable and properly communicated to affected individuals responsible for ensuring product quality. Various changes occur across the business; any change that affects product quality or safety must be controlled and managed.

A number of companies know from experience the issues that can occur from inadequately managing change across the business. In more than one case, companies have relocated manufacturing sites to increase production or changed suppliers to lower risk, but failed to properly assess the change impact and manage the change implementation. The results can have an impact ranging from backorder to having to submit a new product for approval, which ultimately causes companies to suffer financially and patients to suffer from limited treatment supply.

The Typical Scenario: Change Control As A Point Solution

Many of the organizations using electronic systems to track and manage change today do so in isolated point solutions. These types of systems only manage certain types of changes at certain locations. For instance, different manufacturing plants may be managing equipment changes in separate, local systems; and perhaps in a separate system altogether from document changes. While this scenario may allow organizations to meet industry guidance and requirements, disconnected and isolated change management results in a number of challenges and risks, including:

- Limited visibility and little or no sharing of information

- Operational inefficiency due to redundant change controls

- Difficulty assessing risk

- No central repository for change control data

- Disruption to production due to a cumbersome process

- Compliance risk due to inconsistency across the organization

The Better Scenario: Change Management As A Global Solution

Management of change is a complex, detailed process. By comprehensively managing all changes within one system, a great deal of this complexity is eliminated. But it is not just about managing all changes in one system for a given site or plant – global change management encompasses all types of changes across all company locations. The most effective automated global change management systems possess the critical functionality to electronically and securely manage all information in a centralized, scalable, and reliable system, eliminating the potential loss of information and increasing visibility. By managing all change control items in a centralized manner, redundant systems are eliminated and production costs decrease. Corporate liability and patient risk are reduced through consistent and harmonized processes.

By implementing and exercising true global change control, companies are able to standardize the change control process to follow a corporate standard, streamlining deployment efforts and increasing user adoption. Because all relevant data is housed in one database, a global change management system allows for complete and flexible annual product review reporting. Furthermore, a global system provides visibility to changes that impact products manufactured in different global locations, ensuring that if a critical reactive change is made at one site, a proactive change can be made at other impacted locations.

Implementation of a global change control system does not eliminate the need to manage local changes. Just as the visibility afforded by a global change management system helps identify the changes with global impact, it also helps companies identify which changes are local changes that do not affect other sites or countries, as not every change impacts all sites. The initial evaluation and impact analysis of each change is critical – this step will help to clearly define whether a change is global or local. Even if it is determined that a change should be managed locally, the same standard global change management methodology is used, enforcing process consistency.

The Ideal Vision: Global Management Of Change As Part Of EQMS

Tracking and managing change control in an isolated point solution gets the job done, but not without significant challenges. Change management as a global solution evolves basic process management into a best practice. However, the ideal state is to manage global change as part of enterprise quality management.

Change control is connected to multiple elements of an enterprise quality management system (EQMS), including deviation management, audits, registration tracking, CAPA, and training management. Best-in-class EQMS can accommodate a visionary approach to including global change management as a fully integrated element of quality management.

Incorporating global change control as part of EQMS enables full lifecycle management and seamless integration to other quality processes across different business areas, including manufacturing and regulatory affairs. EQMS helps to enforce an automated, consistent, and efficient change control process that accommodates both proactive and reactive changes. By managing change in the same system where CAPA is managed, change control records can easily be linked back to the source. Data centralization enables more effective trending, reporting, and dashboarding, providing clear visibility to all levels of the organization.

When implemented and managed successfully, electronic change control can be a competitive advantage to differentiate an organization from its competition. Companies can realize improved cycle time and faster time-to-market by implementing changes through a consistent process that enables continual product enhancement and evolution. Merger and acquisition strategies are supported through a mechanism to harmonize systems and processes. An EQMS approach to change management also supports global supply chain initiatives, enhanced product quality, and the flexibility to adapt to changing regulations. As a result, the benefits of managing change within the EQMS reach far beyond the realm of quality management.

About The Author

Ashley Watkins is an Industry Solution Manager in Sparta Systems’ Product Management and Strategy group. As a member of the Industry Solution team, Ashley develops product and solution strategy for the pharmaceutical and biotechnology industry. She is responsible for monitoring industry trends and working cross-functionally to ensure Sparta employees have the right industry knowledge to support the pharmaceutical market effort. Ashley received her bachelor’s degree in biology from Boston College and her master’s degree in biotechnology from Columbia University.