PHARMACEUTICAL & MEDICAL SUPPLIES MIXING AND BLENDING

Recommended Blending Equipment For:

Ross serves the requirements of the Pharmaceutical industry, in virtually every industrialized country around the world. We have the experience and production capacity that no other manufacturer of specialty mixing and blending equipment can match.

In the USA alone, we operate five plants, an analytical laboratory and a vigorous R&D program. Overseas, Ross pharmaceutical equipment is being built in our own factories in China and India. Typical applications include mixing, blending, particle size reduction, emulsification, homogenization, powder induction, vacuum processing and more.

Specifications that define a mixer built for a pharmaceutical application reflect a combination of industry standards, and the mixing functions needed for that particular application. A sub-micron emulsion, for example, requires high-shear agitation, vacuum and usually a heat-transfer system. The size of the mixer is determined by the throughput required. To guard against batch-to-batch contamination, CIP and SIP capabilities are usually designed in, along with such devices as air-purged seals and custom designed discharge valves. To ensure a high degree of repeatability and to document the production of every batch, we often add a control system with data-logging capability.

The close connection between specific performance requirements and equipment features is the logical starting point for equipment design. But today, the challenge of specifying and designing a high-performance mixer is more than a two-dimensional process. We regularly address performance needs that are much broader than one particular mixing application. In fact, we often custom design pharmaceutical equipment to meet production needs that have not yet been imagined.

Visit our new Web App to easily search resources, browse images, and learn about Ross Mixing and Blending Technologies in the pharmaceutical industry. http://www.mixers.com/app

CONNECT WITH CHARLES ROSS & SON COMPANY

|

710 Old Willets Path Phone: 631-234-0500 |

CONTACT INFORMATION

Charles Ross and Son Company

710 Old Willets Path

Hauppauge, NY 11788

UNITED STATES

Phone: 631-234-0500

Fax: 631-234-0691

Contact: Sales

APPLICATION NOTES

-

Learn how you can simplify mixer selection for a particular capsule-shell formulation by considering the formulation's viscosity and the appropriate level of shear.

-

Explore the benefits of preparing liquid supplements in a multi-shaft mixer designed for bulk agitation, high-speed solids dispersion, and superior heat transfer.

-

Multi-shaft mixers are versatile systems used in the production of pharma and medical products. Here, we discuss equipment features commonly supplied on multi-shaft mixers for sanitary applications.

-

In the processing of ophthalmic solutions, high-shear mixers are utilized for dissolving salts as well as dispersing viscosity enhancers, antioxidants and other additives.

-

Designed for high-speed powder dispersion, the Ross Solids/Liquid Injection Manifold Mixer is well proven in the preparation of tablet coatings.

-

A majority of pharmaceutical gels are shear-thinning semisolids prepared by dispersing hydrophilic polymers into an aqueous vehicle. Proper mixing requires a good balance between agitation and shear.

-

Dry blending is an indispensable operation in the manufacture of multivitamins, sports supplements, herbal extracts, meal-replacements, green food powders, and other nutraceutical products.

-

For years, blending dense slurries has been a job for the traditional vacuum dryer with a rotating vessel. Today, processors are finding a different blender/dryer can handle the heaviest of materials more easily.

-

This application note offers tips for efficiently containing powders in a ribbon blender to ensure operator safety, prevent cross-contamination and promote easy clean up.

-

The growing demand for prescription and over-the-counter transdermal products encompasses a wide range of uses and conditions, from motion sickness and smoking cessation, to hormone replacements and pain management.

-

Planetary mixers are ideal for wet granulation processes. Advantages include "one-pot" processing, high uniformity and yield, predictable performance, and ease of cleaning.

-

Viscous products possessing shear-sensitive behavior, fragile components or abrasive properties require gentle but thorough mixing.

-

Solid-solid mixing sometimes involves powders that need to be uniformly coated with smaller particles of a different component. The ingredient that is coated onto the bulk material is typically a very small percentage of the batch, thus requiring thorough and uniform blending.

-

To help ensure a long service life out of your capital investment and obtain high quality blends in every single batch, consider the following tips on ribbon blending.

-

Rotor/stator mixers specially designed to generate a powerful vacuum within the mix chamber are capable of inducting a wide variety of solids, from fine powders to friable pellets.

-

Mixing bulk solids into liquid can be challenging not only due to low solubility or resistance to wet-out/dispersion. The difficulty may simply be due to sheer volume.

-

In this age of technological marvels and Internet madness, it's refreshing to see an innovation that isn't the product of an exotic new technology.

-

Granulation requires the addition of binding fluid/adhesive to a blend of powders. The liquid is added at a pre-determined rate to the batch while it is being mixed.

-

In many industries, the challenge of making high quality submicron emulsions has never been more important. Depending on the application, they improve texture, aesthetics, taste, rheology, shelf-life, or even cost. In short, the quality and stability of emulsions play a major role in refining the physical characteristics and effectiveness of numerous end products.

-

Developing a new formulation at the R&D stage can require multiple iterations to arrive at the optimal quality, functionality, cost or a combination of these and other factors.

WHITE PAPERS

-

Explore ideas for selecting the right inline high-shear mixer for your process based on a company’s collective experience as a mixing equipment provider to process industries.

-

Mixer testing simulation trials are necessary to confirm the suitability of a specific mixing strategy. Explore five ways to increase energy efficiency in new and existing mixing processes.

-

Mixing is one of the most common operations in food processing, but comes with challenges -- batch-to-batch uniformity, optimizing blend times, and most importantly: improving cleanliness.

-

Mixing processes vary from one application to another and there are no fix-all solutions.This white paper presents some strategies for improving commonly encountered batch mixing problems.

-

Uniformly dispersing powders into a liquid batch in a practical amount of time is a common problem for F&B manufacturers. This white paper explores five tips for dispersing powders more efficiently.

-

Purchasing new mixing equipment is typically not a hasty event. As with any capital investment, the purchase of a new mixing system ideally requires time and research.

-

Mixing equipment employed in the production of pharmaceuticals and medical devices deal with a higher level of complexity because their use is more specialized. Not one design fits all.

-

This paper provides practical information on the efficient use of specialty mixing equipment for the preparation of low, medium and high viscosity solid-liquid mixtures under low and high shear conditions.

-

When selecting mixing systems, foresight for scale-up is important for long-term success. A quick shift between systems can be the difference between economical success and a financial disaster.

-

Creating an efficient mixing system is a balancing act. Throughput must be balanced against batch size, agitator sizes, motor sizes, shear speeds, viscosity, and many other variables.

-

This white paper explains the rules for mixers and the applications for which two, three, or even four different types of mixers can conceivably provide an optimal tool to achieve your process goals.

-

Vacuum drying is ideal for processing heat-sensitive materials without risk of thermal degradation. It also allows manufacturers to recover costly solvents or safely dispose of any harmful volatiles removed from the closed system.

-

This white paper presents an overview of mixing technologies employed in the dispersion of nano-sized solid particles into liquid. By Christine Banaszek

-

Over the years, static mixer suppliers have developed their own models and formulas for sizing. Charles Ross' LPD/LLPD static mixers are well known for their wide ranging uses in turbulent and laminar flow mixing applications.

-

The aim of this paper is to provide a brief compilation of technical and practical information on high viscosity mixing based on the collective experience of Charles Ross mixing experts.

-

As major developments continue to advance in the areas of renewable energy, green construction, green chemistry and many other markets, new mixing applications and processing challenges arise. The aim of this paper is to provide practical information on certain mixing requirements currently seen within selected green industries and how these production needs are being met through the efficient use of specialty mixing equipment.

-

In processing plants around the world, ribbon blenders are used to mix many thousands of products, from fertilizers and plastic resins to flavored coffees and cosmetics. By Charles Ross and Son Company

-

In processing plants around the world, ribbon blenders are used to mix many thousands of products, from fertilizers and plastic resins to flavored coffees and cosmetics. By Charles Ross and Son Company

-

A few years ago, the process of selecting a mixer for most applications was straight- forward. When increased demand required an increase in production, process engineers were naturally inclined to choose the type of mixer that had worked before in the same application. When they began talking to equipment manufacturers, their questions focused on capacity, auxiliary equipment, projected delivery and price. Many tested equipment before signing a purchase order. By Charles Ross and Son Company

-

A few years ago, the process of selecting a mixer for most applications was straight- forward. When increased demand required an increase in production, process engineers were naturally inclined to choose the type of mixer that had worked before in the same application. When they began talking to equipment manufacturers, their questions focused on capacity, auxiliary equipment, projected delivery and price. Many tested equipment before signing a purchase order. By Charles Ross and Son Company

ARTICLES

-

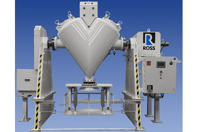

Offering a high level of precision and consistency, ROSS V Cone Blenders utilize diffusion as the main mechanism for mixing. As the V shaped vessel rotates on its horizontal axis, batch materials cascade down, distributing particles over a freshly exposed surface.

-

Fully Rebuilt to perform like brand new, ROSS-reconditioned Double Planetary Mixers are dependable workhorses for high-viscosity and heavy-duty applications. The pictured Reconditioned Model DPM-4 has been meticulously restored to as-new working condition and offers the same standard one-year warranty as a new ROSS Mixer.

-

Capable of processing viscous solutions, dispersions, suspensions, and emulsions with viscosities in the hundreds of thousands of centipoise, the ROSS line of VersaMix Multi-Shaft Mixers is built for longevity, speed and efficiency. The ROSS VMC-100, pictured below, is designed for vacuum operation up to 29.5”Hg and supplied with interchangeable 100-gal mix cans, each fabricated with a 50-psig ASME-code stamped jacket for heating/cooling via glycol. The custom electro-hydraulic system is engineered to fully raise the motor drive in 15 seconds.

-

ROSS Mixers, a leading provider of US-designed and manufactured mixing equipment, offers a Trial Rental Program which offers process managers a powerful tool for optimizing R&D projects before committing to substantial capital investment.

-

The ROSS line of Double Planetary Mixers, which come in a wide range of configurations and sizes ranging from ½ pint to 750 gallons, are dependable workhorses for mixing thick, sticky, or putty-like materials. The pictured Sanitary Double Planetary Mixer Model DPM-4S and Sanitary Discharge System Model DS-4S are fully customized and engineered for efficient processing of medical-grade silicone formulations in a portable workstation.

-

ROSS VersaMix Multi-Shaft Mixers are proudly designed and manufactured in the U.S. to optimize the processing of medium to high-viscosity products. These versatile mixers exhibit outstanding performance and deliver exceptional efficiency across a wide range of applications with viscosities ranging up to several hundred thousand centipoise such as pastes, gels, slurries, and suspensions.

-

A proven workhorse used throughout the process industries, the ROSS V Cone Tumble Blender utilizes diffusion mixing to deliver low impact, highly accurate, and repeatable mixing of powders, high-density powdered metals, granules, pellets, and other free-flowing solids.

-

This laboratory high shear mixer consists of a single stage four-blade rotor that turns at high speed within a stationary stator. Learn how the design promote continuous flow, fast mixing, and more.

-

This double planetary mixer includes two blades that rotate on their own axes while simultaneously orbiting the mix vessel on a common axis. Watch to learn more about this mixing technology.

-

Known worldwide for heavy-duty robust construction, high quality materials, and fine craftsmanship, these ribbon blenders meet the toughest standards for quality and long-term performance.

-

Explore robust and versatile multi-shaft mixers used throughout nearly every process industry. These mixers accommodate a range of shear input and viscosities up to several hundred thousand centipoise.

-

Discover an original equipment manufacturer (OEM) that has the unique capability to provide standard and custom designed mixers to meet your diverse processing needs.

-

OSS Three Roll Mills, used for high viscosity dispersions in many industries, feature true heavy-duty construction, precision workmanship and ANSI 2017-compliant controls package.

-

ROSS is pleased to announce the launch of its newly redesigned website. Mixers.com is faster than ever before, easier to navigate and contains more product information.

-

Designed to minimize risk and maximize productivity, ROSS Ribbon Blenders meet OSHA standards with safety shaft guards (no external moving parts) and limit switches that prevent operation of the agitator when any cover or manway is open. In addition, safety grating can be installed on dedicated charge ports or across the entire blender opening for extra protection and to make it easier for operators to dump bags of dry raw material into the blender.

-

The ROSS X-Series Inline Ultra-High Shear Mixer is designed for efficient high-throughput emulsification, dispersion, and homogenization.

-

ROSS VersaMix Multi-Shaft Mixers with Solids/Liquid Injection Manifold (SLIM) Technology enable fast and efficient large-scale powder dispersion into low-viscosity liquids including resins, oils, melted waxes, emulsions, and aqueous solutions.

-

The ROSS Inline Ultra High Shear Mixer 700 Series is designed for challenging shear requirements, a more efficient alternative to colloid mills which generally suffer from low throughput.

-

Gain insights from a pharmaceutical equipment manufacturer on factors cannabis manufacturers should consider when they're looking to purchase a mixer.

-

ROSS engineers custom blending systems incorporating ergonomic material handling accessories, including bag dump workstations.

-

The ROSS Double Planetary Mixer is ideal for high-precision mixing, granulation and vacuum drying all in a single vessel.

-

ROSS recently designed a new skid system capable of mixing and pumping low to moderately viscous products. The Model VSL-400 design is a custom conical vessel on a movable skid with a progressive cavity pump rated for 10-30 gallons/minute.

-

The ROSS Double Planetary Mixer is available in a reverse-lift design which raises the vessel to the mixing position, rather than lowering the agitator assembly. A reverse lift facilitates improved rigidity and more uniform blade-to-vessel clearances without relying on the floor to be completely level.

-

ROSS inline high shear mixers from 1 through 250 HP accelerate mixing, emulsification and homogenization in both recirculation and continuous modes. A mobile skid allows these machines to be used anywhere in a plant, saving time and money by eliminating the need for multiple mixers separately dedicated to each vessel or product

-

ROSS is pleased to announce the appointment of Ken Langhorn to the position of Vice President of Sales.

-

Conventional agitators are unable to create the fluid circulation necessary to disperse 4%+ powdered CMC dispersions. The consequence of insufficient agitation is the formation of non-dispersed lumps.

-

Companies are reevaluating mixing processes, looking for ways to lower cost, boost production capacity, and improve quality. This article will explain how high-shear mixing can help achieve these goals.

-

In this age of technological marvels and Internet madness, it's refreshing to see an innovation that isn't the product of an exotic new technology.

-

Mixing challenges throughout the process industries are heightened as the viscosity and complexity of the mixture rises. This webinar reviews the numerous options that are available to help select the most efficient mixer for a users requirements.

-

Topics of this webinar include dry blending, high speed mixing, and batch mixing applications for pharmaceutical manufacturing. This webinar addresses the current challenges facing the industry , as well as new innovation that will help with any issues manufacturers are facing.

-

Dry blenders are typically described as being of horizontal, vertical or tumbling designs. On the surface it would seem that each can be used for the same application, but subtle differences usually make one preferable over another. This webinar helps to narrow the choice of the unit for a particular production requirement.

-

The challenge of producing high-quality emulsions, solutions, and dispersions can sometimes be a moving target due to changing market demands, consumer behavior, and product requirements. By Christine Banaszek, Charles Ross and Son Company

-

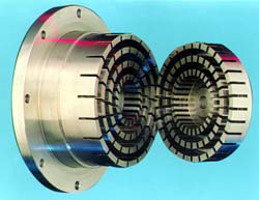

Ross Planetary Mixers are now offered with newly improved sealed and purged gearbox assemblies for sensitive applications requiring the tightest protection against contamination.

-

Charles Ross & Son Company, Vice President of Corporate Operations, Joe Martorana announces the relocation of Ross Process Equipment (RPE) into a new state-of-the-art plant in Pune, India tripling the size of its previous facility.

-

Ross Engineering Inc., a subsidiary of Charles Ross & Son Company, manufactures storage tanks, pressure vessels, reactors and custom fabrication as large as 100,000 gallons at its Savannah facility.

-

Ross manufactures Double Planetary Mixers for heavy-duty mixing of viscous formulations up to around 6 million cP.

-

Popular models of Ross Laboratory Multi-Shaft Mixers are now being offered for trial/rental.

-

Charles Ross & Son Company, a manufacturer of specialty mixing equipment, also designs and builds custom fabricated tanks, stirred reactors, pressure and storage vessels with capacities up to 70,000 gallons.

-

A large number of Ross High Speed Dispersers are now offered from stock for immediate purchase or trial/rental. This robust inventory includes many standard laboratory models for batches as small as 1-2 gallons and production units for vessels up to 500 gallons.

-

Ross introduces the new model HSM-100LSK-I, a multi-purpose laboratory mixer. This bench-top unit is offered with interchangeable mixing attachments including batch and inline rotor/stator sets, various size disperser blades and propellers.

-

Ross Dual-Shaft Mixers are ideal for processing pastes, gels, suspensions, slurries and other viscous formulations. Composed of two independently-driven agitators working in tandem, this system is designed for heavy-duty mixing with the capability of fine-tuning shear levels and flow patterns.

-

Ross Ribbon Blenders cater to a wide range of bulk densities, suitable for industrial or sanitary applications. All units are direct driven by an inverter-ready gearmotor, an integral design superior to belt- and chain-driven blenders that suffer from losses in horsepower and efficiency through slippage.

-

Custom Pharmaceutical Sanitary Tanks, Storage Vessels, Reactors And Transfer Vessels Offered By RossDuring the last two decades, Ross has grown to be one of the best-equipped and most highly respected custom fabricators in North America.

-

Charles Ross and Son Company today announced the in-stock availability several sizes of its Dual Shaft Change Can Mixers.

-

Warren Ang– Product Manager has announced the completion of a new model of the popular line of Ross Ribbon Blenders. The new model is designated as the "42NSD”.

-

Warren Ang– Product Manager has announced the completion of a new model of the popular line of Ross Ribbon Blenders. The new model is designated as the "42NSD”.

-

The new Ross MegaShear Inline High Shear Mixer is the first to combine, high flow rates - up to 500 gpm without an auxiliary pump, high tip speeds - up to 18,000 fpm, and ultra high shear rates, all in a single pass.

-

Charles Ross & Son Company manufactures a wide range of sanitary high shear mixing and dispersion equipment for fine emulsion and homogenization requirements. Many models are available to permit a client to select the exact machine for particular process needs.

-

Charles Ross & Son Company has announced the recent shipment of its 45th - 515 cu.ft. Ribbon Blender.

-

The Ross Inline Solids Liquids Injection Manifold (SLIM) System is great for inducting and immediately dispersing large quantities of difficult to disperse powders such as CMC, fumed silica, and carbomers.

-

Article: Understanding Surfactants And New Methods Of Dispersing Them

-

Charles Ross & Son Company has introduced a new benchtop model of its popular line of High Shear Rotor/Stator Mixers. Ross High Shear Mixers are ideal for dispersion, emulsification, homogenization, and particle size reduction.

-

Video: Ross Double Planetary Mixers

-

Charles Ross & Son Company has announced the design of a new model of its popular line of Ribbon Blenders

-

Ross has introduced a new design option for its popular line of change can mixers, including the PowerMix, Double Planetary, VersaMix, and Dual Shaft designs.

-

Charles Ross & Son Company has announced the introduction of a new model of its proven line of high shear mixers. The PM Model incorporates a rotor/stator configuration that promotes dual flow through a special Delta rotor/stator.

-

Charles Ross & Son Company recently introduced a new Single Planetary Mixer. The mixer is equipped with a custom helical mixing blade allow the mixing of high viscosity paste materials.

-

Ross has announced the introduction of a new Dual-Shaft design incorporating a special helical agitator and high-speed dispersion blade.

-

Bogard Lagman, Executive Vice President of Charles Ross and Son Company, has announced the launch of a new Web site covering the company's line of planetary mixers.

-

Charles Ross & Son Company has recently introduced a new line of Cylindrical Dryers for the chemical process industries

-

The X-Series High Shear Mixer being offered by Charles Ross and Son Company is now being offered with several new optional design features.

-

Charles Ross & Son Company has announced the launch of a new Web site covering the company's line of ribbon blenders and cylindrical dryers.

-

Bogard Lagman, Executive Vice President of Charles Ross and Son Company today announced the availability of a new laboratory model of the SLIM (solids-liquid-injection-manifold).

-

Charles Ross & Son Company today announced the completion of its manufacturing plant expansion in Wuxi, China.

-

Designed for multiple mixing requirements such as high-speed dispersion, emulsification, particle-size reduction and homogenization, the Ross VersaMix Triple Shaft Mixer is now available with Solid/Liquid Injection Manifold or S.L.I.M.™ System

-

Bill Alhofen - Product Manager has announced the introduction of a new model of the Double Planetary Mixer. The new ½- pint working capacity unit is ideally suited for the bench-top research and development of highly viscous materials, up to approx. 6 million centipoise

-

Chris Ross, Vice President-Sales for Charles Ross & Son Company, has announced the recent completion of two special mix/reaction vessels constructed of Hastelloy C and Type- 316 stainless steel

-

Rob Lanham, General Manager of Ross Systems and Controls (SysCon) has announced the launch of a new and comprehensive website...

-

Charles Ross & Son Company has announced availability a customized line of Sanitary Ribbon Blenders...

-

As international markets open and competition intensifies in all of the process industries, plant and process engineers must take special care to avoid making critical business decisions based on experience and presumptions that are no longer relevant...

-

Charles Ross & Son Company recently completed a special dual shaft vacuum mixer for the mixing and dispersion of medium to high viscosity materials...

-

The new Model 100LCI High Shear Mixer being offered by Charles Ross and Son Company is designed to be the most versatile bench-top laboratory mixer available

-

Charles Ross & Son Company today announced that it has received 3A-certification covering of its line of High Shear Inline Rotor-Stator Mixers...

-

Doug Cohen - Vice President -Technical Services of Ross today announced the introduction of a new Model G2 Vacuum Mixer Homogenizer.

This vacuum processor is primarily used for processing by companies that require the ability to process under sanitary conditions. The mixer is constructed entirely of stainless steel and is completely polished for total cleaning between batches

-

The specifications that define a mixer built for a pharmaceutical or cosmetic application reflect a combination of industry standards and the mixing functions needed for that particular application

-

The new Ross MegaShear Inline High Shear Mixer is the first to combine, high flow rates - up to 500 gpm without an auxiliary pump, high tip speeds - up to 18,000 fpm, and ultra high shear rates, all in a single pass

-

The Ross line of High Shear Mixers includes conventional high-speed dispersers, batch and inline rotor-stator mixers, multi-shaft designs, and the new SLIM (solids liquids injection manifold

-

In processing plants ribbon blenders are used to mix many thousands of products, from fertilizers and plastic resins to flavored coffees and cosmetics

-

There’s a big story behind those small, unassuming gray boxes on your plant wall, the ones that enclose your high-voltage switches.

-

Ribbon blenders and vertical cone screw blenders are found in many plants, and in many ways they perform a similar function on the process line. But the differences in their design – and in the advantages they offer – are far more important than their similarities

-

Wetting out powders like fumed silica, TiO2, gums and thickeners is one of the toughest challenges our customers face – in virtually every industry we serve, from foods and pharmaceuticals to coatings and the CPI

-

Every process engineer who has worked with powders such as fumed silica, CMC, guar, xanthan, carageenan, alginates and other thickeners has come face to face with one of the toughest challenges in mixing. Many of the powders that are most often used in the process industries are hard to wet out and mix...

-

Ross Engineering, Savannah, GA. offers extensive custom vessel fabrication capabilities.

-

Oleoresin extraction, the starting point for many varieties of flavor development, is a long, labor-intensive and costly process...

-

Richard Ross today announced the promotion of Gladwyn "Bogard" Lagman

-

Whether you're considering a tumble blender for your process or shopping for a suitable piece of blending equipment, here are 10 things you should think about before making the final decision.