Podbielniak Contactor: A Unique Liquid-Liquid Extractor - Part 2

Gitesh Dubal, B&P Process Equipment and Systems LLC

Introduction

Limitations

Advantages

Applications

Other Promising Applications

Summary

References

Introduction (Back to Top)

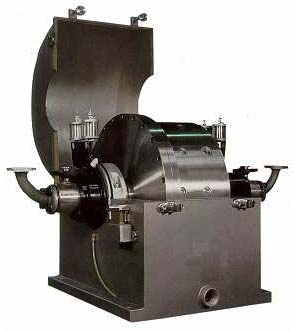

The Podbielniak Contactor, popularly known as the "Pod," is a liquid-liquid centrifugal extractor and separator (Figure 1) providing differential countercurrent extraction in a compact hermetic rotor. Used successfully for more than fifty years to solve extraction problems in the chemical process industry, the Pod can provide up to 5 theoretical stages in one unit and can separate liquids with a specific gravity difference as low as 0.01. The Pod has a bright future in new technologies as indicated by ongoing research in non-conventional applications.

Figure 1: The Podbielniak Contactor, aka ‘the Pod'

Part 1 of this two-part article discussed general operation of the Pod. Part 2 will now examine limitations, advantages, and applications.

Limitations (Back to Top)

Many Pod applications involve process liquids with some solids, which tend to build up on elements over time. This decreases effective internal volume, and ultimately decreasing extraction and separation efficiency. These solids have to be physically or chemically removed, and require a shutdown of the process. This limits the Pod to applications with less than 40% solids volumetrically. The operating time between shutdowns and total down time vary on the nature and amount of solids in the feed. In addition, the Pod capacity is derated for viscous materials, as the resistance to the flow of liquids is increased.

Advantages (Back to Top)

Robust mechanical features along with distinctive process design make the Pod a unique contactor for extraction and separation. The Pod is a differential countercurrent centrifugal extractor, (opposed to the batch-wise countercurrent configuration in mixer-settlers and most centrifuges) which increases extraction efficiency at a given flow rate ratio. Internal clarification zones allow handling of easily emulsified systems resulting in both effluent streams that are free of entrainment in most cases. The unique design of the Pod reduces solvent usage and operating costs while producing better product at higher yields in a safer environment.

The hermetic design allows complete enclosure of process fluids, resulting in these benefits:

- Safer operation with hazardous solvents due to complete enclosure

- Reduces the possibility of product contamination

- Prevents oxidation or degradation of product by avoiding contact with air

- Solvent and product losses are minimized.

The Pod has a small rotor volume compared to mixer-settlers and extraction columns, which offers the following advantages:

- Relatively high capacities due to multiple Xg force and generation of large amount of interfacial area in a small geometric space

- Small rotor and high flow rate leads to short residence time—important when product degenerates at extraction conditions

- Reduces capital investment required when costly material of construction is required

- Small footprint enables the rotor to be added to just about any existing plant.

The unique Pod design offers the following distinct advantages over other liquid-liquid extraction centrifuges:

- Horizontal orientation, resulting in increased stability

- Combination of Xg force along with low shear inside the Pod, reducing the possibility of emulsion formation

- Separation of liquids with specific gravity gradient as low as 0.01

- Mechanical seals allowing any permutation of the process liquids in order to provide safest handling of the materials involved. Hazardous solvents are passed across the inner seals so that accidental leaks to atmosphere are prevented

- As the fluids enter and leave at the same axial position, the liquids do not lose potential energy in the centrifugal field. Hence, power requirements are low as only external windage and internal friction needs to be overcome.

Applications (Back to Top)

Due to its unique design, the Pod has been successfully used in hundreds of applications, ranging from lube oil extraction to vaccine production. There are three main types of applications: extraction, separation and simultaneous separation with countercurrent wash. Extraction constitutes the majority of Pod applications, with up to five theoretical stages extracted in a single unit.

Pharmaceuticals

In pharmaceuticals, the Pod has been used to extract antibiotics such as penicillin, erythromycin, and tylosin. The Pod has also been used in biological applications, including hormone and vitamin extraction and food processes like edible oil processing and citrus flavor extraction.

One of the Pod's first applications, in 1945, was the extraction of penicillin. Generally, two Pods are used in countercurrent series, giving a 90-95% extraction efficiency at a broth to solvent ratio of 2:1. Filtered broth results in 98% extraction at a broth to solvent ratio of 4:1. The hermetic design along with short contact time in the Pod enables mass production of penicillin, as it degrades over time at extraction conditions.

Chemical

The Pod has worked well in applications where an organic product stream is purified by reacting the impurities out using an acid or a caustic wash. The Pod has been used for many applications like acrylics, aromatics, fumaric acid, plasticizer refining, polycarbonate washing, insecticide and herbicide manufacturing, acid and caustic treating of lube oil, etc.

For example, in plasticizer refining tricresyl phosphate is countercurrently contacted with a mild caustic solution at a 1:1 ratio to remove acidic impurities like phenols and cresols. The intermediate product is then contacted with wash water countercurrently in the second Pod at a 1:1 flow ratio to wash out the salts. The acidic impurities are decreased from 0.5-1% to 0.03-0.07%.

Liquid ion exchange, where cations or anions are exchanged between two liquids, involves a chemical reaction between the product and the ion exchanger in the organic solvent. Hence, the reaction kinetics governs the extraction rather than surface area formation (as in most Pod applications). There are two steps in this process: Loading, when the solvent is loaded with the product, and stripping, where the product is extracted back into the aqueous phase. Liquid ion exchange applications such as hydrometallurgical extractions in mineral processing, citric acid, and waste dye extraction.

During waste dye extraction waste sulfonic acid dye is extracted from an aqueous waste stream via liquid ion exchange in the Pod. The loading step has an efficiency of 97% while using a 23:1 wastewater to solvent ratio. After passing through the stripping stage, the wastewater is concentrated volumetrically by a factor of 700. Hence, the generation of wastewater is drastically reduced. The solvent is recirculated in a closed loop.

Simultaneous Separation and Countercurrent Wash

This unique setup allows handling two process steps in one unit operation. A mixed feed is introduced through the LLI port. The two liquids are phase separated, and the lighter liquid moves towards the shaft. Water is introduced from the HLI port, which counter-currently washes out the exiting light liquid of any water-soluble impurities. The Pod has been utilized for such processes as naphthenic acid recovery, continuous soapstock acidulation, parrafin neutralization and washing, polyol washing, etc.

Food

Vegetable oil degumming is used to recover lecithin from unrefined oil. A mixture of oil and hydrated gums is introduced near the rim. The heated feed is mixed with 2-3% water or steam, which dissolves the lecithin out. 90% of the lecithin is removed from the oil using the Pod.

Other Promising Applications (Back to Top)

Extensive research is going on to introduce the Pod into non-conventional, emerging separations such as:

- Supercritical fluid extraction, used in an increasing number of chemical, pharmaceutical, and food applications

- Phytosol extraction, developed by Advanced Phytonics, a UK-based R&D company. Typical applications include fragrance and flavor extraction, fermentation broth extraction, and wastewater treatment.

Summary (Back to Top)

Unique processing capability along with robust mechanical design has made the Pod highly successful in hundreds of extraction and separation applications. With nearly one thousand Pods built and used successfully, the future of the Pod looks even brighter as new and unconventional applications are on the horizon.

- Todd, D. B., Davies, G. R., Kaiser H. R. "Controlled Centrifugal Separation of Liquids", Third Symposium on Hazardous Chemicals Handling and Disposal, 1972.

- Todd, D. B., Davies, G. R. "Centrifugal Pharmaceutical Extraction", Filtration and Separation, November/December 1973.

- McHugh, M.A., Krukonis, V.J. "Supercritical Fluid Extraction: Principles and Practice", Butterworth-Heinemann Publications, Second Edition, 1994.

- Ruthven, D.M. "Encyclopedia of Separation Technology" Wiley Interscience, 1997.

- Perry, R. H., Green, D. W., "Perry's Chemical Engineer's Handbook", sixth edition, McGraw-Hill, 1984.

For more information: Gitesh Dubal, Process Engineer, B&P Process Equipment and Systems LLC, 1000 Hess Ave., Saginaw, MI 48601. Tel: 517-757-1300. Fax: 517-757-1301.