FEATURED ARTICLES

-

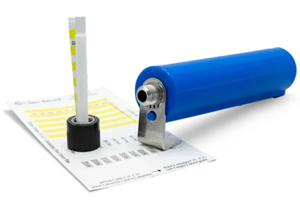

A Comprehensive Guide To Sampling Protocols And Robust CCI Testing

Effective CCI testing hinges on strategic sampling and statistical rigor. Learn why 30 samples matter, how positive controls validate defect detection, and why risk assessment ensures long-term reliability.

WHITE PAPERS & CASE STUDIES

-

Aseptic Process Design And Simulation Under Annex 1 Guidelines

Gain insight into how Annex 1 reshapes aseptic process validation, as well as into risk reduction by design and why isolators are redefining modern sterile manufacturing standards.

-

Inline Checkweighing Of Packaged Products In Manufacturing

Accurate inline checkweighing is vital for quality control. Learn how system design, software, and regulatory compliance work together to overcome high-speed production challenges.

-

Cryogenic Storage Of IV Bags For Cell And Gene Therapies

Cryogenic storage can compromise packaging integrity for cell and gene therapies. Learn how vacuum decay technology detects micro leaks and ensures product safety under extreme conditions.

-

Make Your Production Sites Adaptable And More Efficient

Pharma faces mounting complexity and tighter margins, demanding agile, future-ready production. Discover how smart manufacturing enables faster adaptation and continuous therapy availability.

-

Accelerating Manufacturing Digitalization With Low-Code Development

Learn how a low-code approach to MES systems delivers speed, flexibility, and compliance, empowering manufacturers to overcome bottlenecks and embrace digital transformation with confidence.

-

Quality By Design In The Pharmaceutical Industry

Real-time release and digital quality management, powered by PAT, are driving efficiency and compliance, reshaping how manufacturers achieve speed, consistency, and competitive advantage.