3D Printing Services

Proto Labs offers an selection of 3D printing services that are ideal for rapid prototyping, complex designs, multi-part assemblies, and functional, end-use parts. Options consist of stereolithography (SL) for thermoplastic-like parts, selective laser sintering (SLS) for industrial-grade nylon components, and direct metal laser sintering (DMLS) for fully dense metal production.

Stereolithography

Stereolithography

Stereolithography (SL) is an additive process that utilizes an ultraviolet laser focused to a small point to draw on the surface of a liquid thermoset resin, turning the liquid to a solid. The process is repeated in thin, two-dimensional cross-sections that are layered to form complex three-dimensional parts. Proto Labs’ SL delivers the widest material selections, best feature resolution, and the smoothest surface finish. Click here for more information on the SL process, quoting, and design guidelines.

Selective Laser Sintering

Selective Laser Sintering

Selective laser sintering (SLS) is an additive manufacturing process in which a CO2 laser is used to draw onto a hot bed of thermoplastic powder, where it is lightly sintered, layer by layer, into a solid. The Proto Labs SLS process uses a nylon-based powder so that parts are tougher with a rough surface, but lacking in finer details. This process offers larger build volumes, parts produced with higher complexities, and durable prototypes. Click here for more information on the SLS process, quoting, and design guidelines.

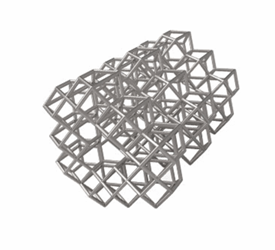

Direct Metal Laser Sintering

Direct Metal Laser Sintering

Direct metal laser sintering (DMLS) is an additive manufacturing process that works via a laser system drawing onto a surface of atomized metal powder, layer by layer, to weld into a solid. Proto Labs’ DMLS allows for prototypes to be functional hardware made from the same material as production components by using a variety of alloys. The layer-by-layer process makes it possible for organic geometries to be formed with internal features and challenging passages that could not be otherwise machined. Click here for more information on the DMLS process, quoting, and design guidelines.