3M Announces new technology for metered dose inhalers

Oligolactic acids provide new formulation options for drug delivery with hfa-based mdis

Table of Contents

Providing sustained release

About 3M Drug Delivery Systems

During the recent Respiratory Drug Delivery VII Conference held in Tarpon Springs, Florida, researchers from 3M Drug Delivery Systems (St. Paul, MN) presented findings on a new technology for oral drug delivery. 3M scientists have developed a novel excipient using oligolactic acid (OLA) that increases formulation options for a variety of drugs in hydrofluoroalkane (HFA)-based metered dose inhalers (MDIs), and additionally may provide for the sustained release of pharmaceuticals within the lungs.

"When used in MDIs, OLAs function as suspension aids or solubilizers in HFA propellants while also having the potential of providing sustained release of drugs within the lungs, using a non- toxic, short lived, and biocompatible family of excipients," said James Stefely, research specialist at 3M DDS. "The net effect minimizes side effects and maximizes efficacy during the pulmonary delivery of drugs from MDIs to patients suffering from asthma and other respiratory diseases. These are highly desirable results, which expand the range of compounds capable of being formulated in the MDI."

After the replacement of chlorofluorocarbons (CFCs) with HFAs as suitable propellants in MDIs, researchers found suspension aids that functioned in CFCs typically were insoluble in HFAs. Cosolvents have been used to increase solubility, but can be problematic in their ability to rapidly provide robust formulations for multiple classes of drugs. This presented a need for the development of suspension aids that could be utilized in HFA-based MDIs and would function well in the absence of a cosolvent. 3M DDS researchers found that oligomers of lactic acid (OLAs) increased the solubility or suspendability of a wide variety of drugs in HFA propellants.

"The transition from CFC to HFA propellants presented a difficult challenge to the pharmaceutical industry," Stefely added. "The difference in their chemical and physical properties left us with the need to design a suspension aid that would work with HFAs. The development of OLAs seems to have filled that need and has proven to be extremely useful in enabling the rapid screening and development of new drug formulations for pulmonary delivery."

The solubilizing ability of OLAs has been tested on several classes of drugs and the formulations were proven very suitable for pulmonary delivery. OLA solutions provide much wider dosing ranges than are available by cosolvent-based solution or suspension formulations. The versatility of the OLAs also provides a method to quickly obtain prototype solution and suspension formulations, thereby reducing development times.

Providing sustained release

According to 3M Drug Delivery Systems Division scientist Chet Leach, a common problem limiting the success of some treatments under development is that the drugs are often transported across the lung too quickly, before interacting fully with the target receptors. "To compensate, much larger drug doses are frequently administered, leading to over exposure, increased blood levels of the drug and unwanted side effects. Therefore many potentially useful drugs are eliminated from further consideration. A long sought after goal in respiratory therapy has been the ability to formulate drugs in a sustained-release dosage form. In recent studies, OLA biomatrices were shown to improve efficacy when formulated as sustained release agents with four different classes of inhaled drugs including steroids, immune response modifiers, phosphodiesterase-IV (PDE-IV) inhibitors and 5-Lipoxygenase (5-LO) inhibitors."

A key factor in determining the effectiveness of inhaled drugs is their residence times within the lungs. In recent studies, the use of OLA with multiple classes of drugs demonstrated that the combination increased the lung residence time of the drug, thereby increasing its efficacy and potency and enabling the use of a lower dose. These findings show that this new technology can contribute to greater effectiveness for metered dose inhalers and other aerosol devices in the treatment of asthma. The OLA formulations are adjustable to provide sustained or immediate release.

About 3M Drug Delivery Systems

3M is not the first name that comes to mind when you think of drug delivery companies, but over the years 3M has parlayed its vast materials expertise into important medical product lines.

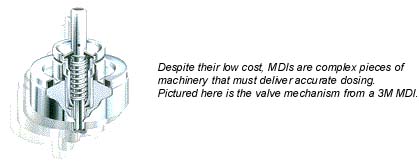

For example, 3M makes more than 50 million metered dose inhalers each year, and more than half of all MDIs worldwide use 3Ms metered dose technology. The company provides development and contract manufacturing as well as components, such as metered dose valves and canisters. 3M Drug Delivery works with several major pharmaceutical companies on development, manufacturing, and component technology.

Drugs inhaled into the lungs have many advantages over other delivery methods such as capsules and injections. Inhalation delivers chemicals into the body quickly and effectively. For medications designed to work on the lungs themselves, direct delivery through inhalation means smaller doses and therefore fewer side effects than with oral therapy. This is why 3M's latest development, which broadens the scope of pharmaceuticals that may be formulated in inhalable form, is so significant.

For more information: Sue Thoreson, 3M Drug Delivery Systems, 275-3E-10 3M Center, PO Box 33275, St. Paul, MN 55133-3275. Tel: 800-643-8086. Fax: 651-633-2072.

Edited by Angelo DePalma

Managing Editor, Drug Discovery Online and Pharmaceutical Online