Advanced Extraction Technology from U.K. Licensed to R.C. Costello

Contents

Introduction

Solid-Liquid Extraction

Continuous Liquid-Liquid Extraction

Resin Manufacture/Regeneration

Introduction (Back to Top)

R.C. Costello & Associates (Redondo Beach, CA) has become the North American licensor of advanced phytonics, a novel extraction technology developed by U.K.-based Advanced Phytonics Ltd. Advanced Phytonics (AP) uses nonflammable solvents called phytosols, at low pressure, to extract selective compounds from pharmaceutical, specialty chemical, and botanical preparations. Target markets include drugs, nutraceuticals, biotechnology, hydrocarbons, chemicals, and wastewater.

Phytosols are nothing more than non-chlorinated fluorohydrocarbons—environmentally friendly refrigerant gases—which Advanced Phytonics has been pushing as economically viable alternatives to conventional organic solvents and supercritical carbon dioxide.

Costello claims phytosols and the AP process has "major advantages" over organic solvents since it is non-flammable, non-toxic, non-corrosive, odorless, inert, and highly selective. Phytosols are easily modified by adding cosolvents, and their low boiling points minimize thermal degradation and the loss of volatile compounds during isolation.

The main advantage over over supercritical carbon dioxide (SCCO2) is lower equipment costs, since high pressure equipment is not required. The other principal benefit is a much lower working pressures for liquefication. For example tetrafluoroethane, a phytosol, liquefies at 5 bar gauge, while SCCO2 is only useful as a solvent at pressures well in excess of 100 bar gauge. Low working pressures also translate into lower operating costs. Also, unlike CO2 phytosols do not form acids when exposed to water.

Solid-Liquid Extraction (Back to Top)

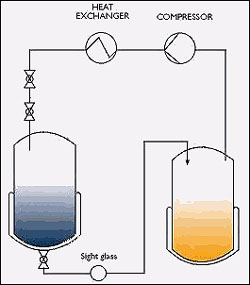

Components for solid-liquid extraction using phytosols are familiar to most chemical engineers: a stirred extraction vessel or an extraction column, evaporation/collection vessel, gas compressor and heat exchanger. Phytosol is evaporated with the aid of a gas compressor, re-liquefied and passed through the medium, which can be either a stirred batch or a packed column. Phytosol rich in product (or contaminant) passes through an inline filter into the evaporation vessel. By carrying out this operation continuously, only a small inventory of phytosol is required. At the end of the extraction, Phytosol flow is redirected into a storage cylinder and the extracted material is recovered from the evaporator.

The AP process using phytosols has been used for extraction of essential oils and biologically active compounds from solid botanical materials. According to Costello such extracts show enhanced biological activity compared with conventional extracts. Data is on file at Costello's for extraction of anti-oxidants, cytotoxic agents, and an anti-infective.

Phytosol liquid-liquid extraction may be used to remove trace impurities from final drug products. For example, amoxycillin and ampicillin with dichloromethane contents of up to 0.2% have been successfully and easily decontaminated.

Continuous Liquid-Liquid Extraction (Back to Top)

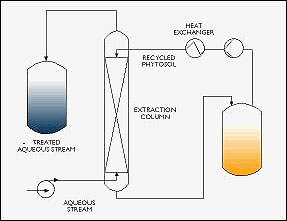

Phytosols work similarly for continuous extraction. Components shown above include an extraction column, treated aqueous collection vessel, evaporation/ isolation vessel, gas compressor and a heat exchanger. Phytosol is continuously evaporated, re-liquefied and recycled through the column in a down-flow mode. When steady state is attained, rich aqueous stream is introduced through the column in a counter current fashion. The now rich Phytosol continues to be fed into the evaporation vessel, evaporated (distilled) and re-liquefied. A multi-vessel design enables the process to be run in a continuous fashion. Alternatively, efficient extraction can be achieved using a centrifugal mixer/ separator. Podbielniak equipment has been successfully used in a variety of applications. This has proved extremely useful in cases where the morphology of the aqueous stream may inhibit efficient phase separation.

Liquid-liquid applications of the process include:

- Removal of organic solvents from aqueous process or effluent streams. For example butyl acetate, used for the extraction of phenylacetic acid post de-acylation of benzyl penicillin, is effectively removed from the aqueous 6-aminopenicillin solution.

- Extraction of metabolites from clarified or mobile fermentation broths. Examples of metabolites successfully extracted are pleuromutilin and milbemycin.

Resin Manufacture/Regeneration (Back to Top)

Manufacturers of polymeric adsorbent resins must remove trace chemicals from their products before shipping them. Similarly, users need to clean up resins between runs. According to Costello, phytosols can be used for both applications, avoiding the need for hot methanol/water treatment post-manufacture or of caustic agents between uses. This application has been demonstrated for removal of phenol and dichloromethane from a polymeric resin (Purolite Macronet) and toluene from activated carbon (Carbon Link SI 1).

R.C. Costello & Assoc., Inc. provides engineering design and construction services, environmental engineering services, and process safety services to the chemical, pharmaceutical, food, and oil & gas industries.

For more information: Rocky Costello, President, R.C. Costello & Associates Consulting Engineers, 1611 S. Pacific Coast Hwy., Suite 210, Redondo, Beach, CA 90277. Tel: 310-792-5870. Fax: 310-792-5877. Email: rcca@rccostello.com.

By Angelo DePalma