AEA Updates Batch Processing Lifecycle Software

BDK 2000 provides a combination of capabilities that cover chemical synthesis, reaction engineering, and such critical batch unit operations as crystallization, solid-liquid separation, and drying. According to Hyprotech, the program enables:

- Rapid selection of optimum chemical synthesis and manufacturing routes, including scale-up implications

- Documentation transfer throughout the project to support regulatory compliance

- Optimized supply chain, waste processing, equipment allocation and facility utilization costs.

Among the key capabilities of BDK 2000:

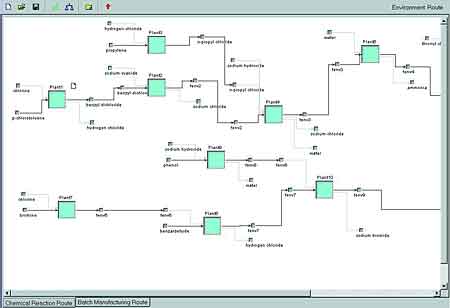

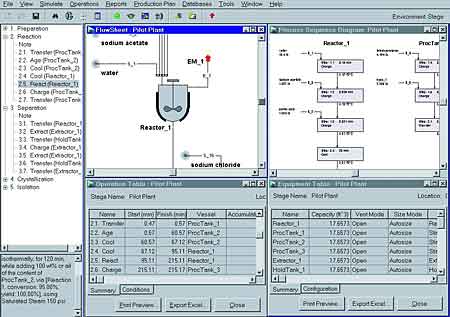

- Process Development/Viability. Screen alternate chemical routes interactively using sensitivity analysis scenarios for such factors as cost and waste generation. Once the user identifies the best route, BDK produces an outline flowsheet and batch recipe.

- Information Sharing/Technology Transfer. Share projects and data among a project team using an online repository while fully documenting the development process.

- Extension Models/Model Layering. Incorporate custom models directly into BDK using spreadsheets, Visual Basic script, or ActiveX components. BDK provides more than 70 customizable built-in models.

- Technology-based Modeling. Hyprotech plans to ship its rigorous crystallizer and dissolution extension models with BDK 2000. Models covering dryers and other key batch equipment will ship with future releases.

- Custom Recipe Text. Hyprotech's fully customizable recipe text enables companies to match corporate standards, as well as switch between different types of recipes (benchtop, pilot, commercial) and languages (English, French).

- Custom Reporting. Automatically generate corporate reports using the Automation capabilities of BDK.

- Component Properties. Create and track customized properties, such as efficacy or oxygen demand, to measure the effects of a recipe change.

- Services. Send process wastes to an incinerator or other specific waste treatment facility to identify peak usage, trends, costs, and other factors.

The program was developed with feedback from the BDK Steering Group, a committee of leading batch processing companies that help guide the technical direction of BDK. In addition, BDK 2000 incorporates new technology offered by Hyprotech or through alliances with VisiMix (VisiMix) and GSE Systems (BatchCAD). GSE also provides core simulation capabilities to Avantium Technologies, a contract provider of high-speed experimentation and simulation (HSE&S) capabilities for contract

BDK is a component of Hyprotech's BaSYS system of software and services for the batch processing industries. BaSYS combines software tools, in-depth process knowledge, and layered models to enhance overall business performance. BaSYS also includes BatchCAD (batch reaction kinetics and reactor modeling), VisiMix (mathematical modeling of laminar and turbulent mixing processes), SPS Process Manuals (comprehensive knowledge bases on separation technologies), and Process Consultancy (specialists to provide in- depth process expertise).

For more information: Hyprotech Ltd., AEA Technology, Suite 800, 707 8th Avenue SW, Calgary, AB, Canada, T2P 1H5. Tel: 403-520-6000. Fax: 403-520-6060.

By Alan S. Brown