An Optimal Upstream Process Development Approach To Increase The Titers Of The Monoclonal Antibodies (mAbs)

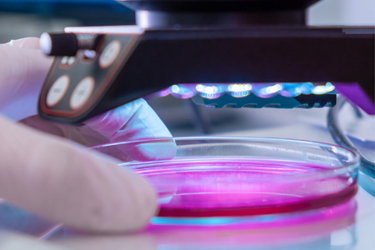

A well-defined upstream development strategy is critical to ensuring the production of biologics in sufficient quantity and purity for regulatory approval and successful commercialization. Key decisions made during upstream development, such as clone selection, Design of Experiments (DOE) optimization, media and feed formulation, and bioreactor scaling, directly impact the titers and purity of the final biologic product. This case study illustrates how Aragen leveraged nearly two decades of expertise in biologics to help a client develop an efficient upstream process for a novel monoclonal antibody (mAb), resulting in a more than 100% increase in titers.

The client was focused on developing a specific mAb targeting a bacterial species responsible for several challenging infections, including pneumonia and cystic fibrosis lung infections. This mAb was intended as a first-in-class adjunctive therapy. Aragen was engaged to identify the high-producing clone and establish an upstream process development protocol that would enhance therapeutic titers at various bioreactor scales, ultimately streamlining GMP manufacturing. Through this collaboration, Aragen helped the client optimize the production process, laying the groundwork for the successful development and scaling of this promising therapeutic candidate.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Pharmaceutical Online? Subscribe today.