Argonaut, Symyx Collaborate on Parallel Catalyst Screening System

"Endeavor marks Argonaut's expansion into the process development and fine chemicals markets," said David Binkley, Argonaut president and CEO. "It adds a new dimension to our corporate mission to enable chemists throughout R&D to increase productivity through parallel chemistry."

Along with eight reaction chambers, Endeavor permits reagent introduction by syringe (top insert). Each reaction chamber is individually stirred (bottom insert).

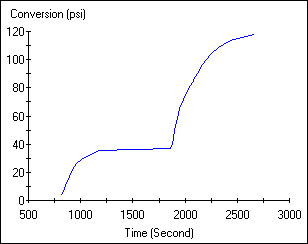

Endeavor performs eight simultaneous, independent, pressurized gaseous reactions while measuring gas consumption in each vessel over the course of the reactions. Argonaut claims that by performing catalyst runs in parallel, in small volumes, and by collecting data in real time, chemists can save weeks of development time on a typical project involving catalysts.

The Argonaut-Symyx collaboration grew out of mutual admiration. Symyx had earlier designed a parallel synthesizer with variable pressure and temperature capability—very desirable features to Argonaut—but the system was unsuitably large and expensive for bench chemists. Symyx was also using one of Argonaut's parallel synthesizers and liked it. Could small size, reasonable cost, and improved functionality be combined?

"We recognized that the ability to control temperature and pressure independently, in individual reactors, was something industry was looking for," said Argonaut product manager Gregor Hsiao. "We knew Symyx's idea had potential. So we decided to adapt it for benchtop use. It's the first system that allows you to control temperature and pressure in individual reactor vessels." Endeavor represents a good value and is easy to use, says Hsiao. "At $70,000, it's at the right price point. Users can learn to operate it in an hour or less."

Endeavor measure gas uptake in real time. Data may be sent to database or spreadsheet programs for later analysis.

Features and Benefits

Endeavor combines multiple reactor capability that users expect from a good parallel synthesizer, plus some features that make it attractive for catalyst development. In particular, all reaction conditions in each reactor can be controlled separately—a welcome departure from one-temperature, one-pressure systems that only allow reagent changes. In summary, Endeavor features:

- Temperatures up to 200°C

- Independent temperature control for each reactor

- Individual pressure setting up to 500 psi through keypad settings

- Vigorous stirring for viscous mixtures; independent magnetic actuation for each stirrer

- Individualized pressure and gas monitoring for each reactor

- Output to database or spreadsheet software

- Add reagents via syringe

- Disposable glass insert for each stainless steel reactor (no cleanup)

- Operation within a dry box

Disposable glass liners reduce cleanup to zero.

About the Companies

Founded in 1994, privatelyheld Argonaut Technologies made its name in discovery-stage chemical synthesis. Its collaboration with Symyx gives Argonaut a foothold into materials discovery and process development. Argonaut's products include organic synthesizers, software, chemical resins, and reagents for solution-phase and solid-phase chemistry. The company has has technical centers in San Carlos, CA; Basel, Switzerland; and Tokyo, Japan.

Symyx arose from the efforts of two great Silicon Valley scientist-entrepreneur-personalities: Affymax/Affymetrix/ALZA founder Alejandro Zaffaroni and Novartis/Scripps chemist Peter Schultz. A public company, Symyx develops and applies combinatorial technologies to the discovery of materials for the life sciences, chemical, and electronics industries, primarily through collaborations.

For more information: Gregor Hsiao, Product Marketing Manager, Argonaut Technologies, 887 Industrial Road, Suite G, San Carlos CA 94070. Tel: 650-598-1350, ext. 112. Fax: 650-598-1359.

By Angelo DePalma