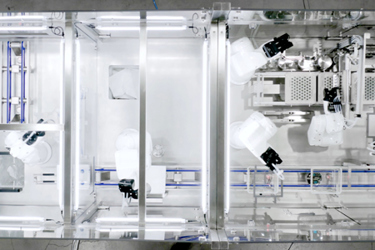

Aseptic Small Scale Batch Filling & Closing Machines: ASEPTiCell®

Today’s injectable drug products require flexible fill/finish systems that can efficiently process medium-sized clinical and commercial batches while meeting all cGMP requirements for cleanliness and sterility.

AST’s ASEPTiCell® has a unique blend of automated capabilities to ensure your sterile products, whether clinical or commercial, are processed in strict accordance with cGMP requirements. The system has the flexibility to adapt to your process requirements and container options alike, and its ability to process all ready-to-fill vial, syringe, and cartridge formats allows you to bring drug products to market cost-effectively.

By integrating standard process modules into an advanced robotic fill/finish system, the ASEPTiCell provides unrivaled flexibility for cGMP aseptic production of Ready-To-Use Vials, Syringes, and Cartridges, making the ASEPTiCell the ideal fill/finish system for small to medium batch size commercial drug product applications.

The ASEPTiCell can be configured with advanced system features and capabilities to tailor the equipment for each unique application. The system meets the highest standards for aseptic processing by providing features such as environmental monitoring, multiple product dispense system options, in-process fill weight control, and electronic batch record reporting.

Small & Medium Batch Capabilities

The ASEPTiCell is easily configured to process all ready-to-use, nested, vial, syringe and cartridge formats for small and medium commercial batches. The use of highly reliable robotics enables a complete system changeover in as little as thirty minutes. The system can include automated lyo loading and unloading.

- Vial Filling, Closing, and Sealing

- Syringe Filling and Closing

- Cartridge Filling and Closing

- Lyo or Lyophilizer Integration

Flexible & Modular System Design

In order to meet a wide range of customer and application needs, the ASEPTiCell has a modular design that provides our customers a system that is tailored to their application requirements without the cost and risk associated with customization. Available modules include:

- Semi-Automatic (SABO) or Automatic (ABO) Bag Opening

- Automatic Tub Opening (ATO)

- Automatic Filling & Closing (FCM)

- Lyo Prep (LPM)

- Vial Sealing (VSM)

Aseptic Barrier Technologies

ASEPTiCell is integrated with isolator-barrier technologies to fully enclose and tightly control the aseptic environment for ideal conditions for processing sterile drug products. The system can be configured with a Restricted Access Barrier System (RABS) or an aseptic isolator to provide uninterrupted aseptic conditions during production. With isolator integrated systems, the ASEPTiCell is completely compatible with repeated in-situ bio-decontamination using hydrogen peroxide to further enhance the sterility assurance of the system.

- Restricted Access Barrier System (RABS)

- Isolator – with in-situ bio-decontamination using hydrogen peroxide (VHP)

Applications:

- Small to medium batch production of commercial and clinical materials

- Biologics, proteins and potent products

- Filling of toxic and cytotoxic materials

- Multi-product aseptic filling facilities

- Pilot-scale cGMP manufacturing