AstraZeneca's Steps In Implementing A "Technology Uplift" Of Its Microbiology Labs

By Miriam Guest, associate principal microbiologist, AstraZeneca

A robust transformation strategy has short-, mid-, and long-term aims. It has the flexibility to respond to events and changing landscapes, as well as an implementation plan, with clear prioritization of activities. Change can sometimes be difficult to navigate; however, with appropriate engagement at all levels, from laboratory users to senior stakeholders, it is possible to deliver improvements in the pharmaceutical microbiology laboratory.

The focal point for all work executed in the pharmaceutical microbiology laboratory is the assurance of patient safety. The tests and activities that take place on a daily basis are executed with the primary intention of assuring quality and supporting patient safety. The pharmaceutical industry is committed to ensuring products are both safe and efficacious, and this is achieved by following regulatory guidances, collecting and responding to data, and approaching decisions with scientific rigor.

The modern microbiology laboratory is often busy, with a wide range of activities taking place. This may be final product testing, or it may be auxiliary support, such as quality control release checks on nutrient media. The instruments and equipment available to microbiology technicians vary from laboratory to laboratory, and considering a network-wide approach to the modernization of microbiology labs has been a cornerstone of AstraZeneca’s technology strategy.

Working within a multi-site global organization, there are many potential areas where harmonized approaches can be achieved, both from a quality principle perspective and from the adoption of new technologies.

This article outlines a strategic approach to new technology evaluation and deployment.

Reasons To Have A Technology Strategy

When considering the heavily regulated pharmaceutical industry, it is important that any changes are carefully studied and managed. Prior to changing an existing practice, it is important to weigh the hurdle of change, and the following aspects should be considered at a minimum:

- Current state

- Risks associated with the current ways of working

- Regulatory impact of changing the current state

- Regulatory filing impact

- Site audit impact

- Cost of goods

- Hands-on time of both the existing and proposed changed practices

- Time to results

- Broader risks and benefits of the change

The regulatory authorities around the world provide guidance and help steer the use of modern methods and advanced technologies; this has been encouraged for decades. Major regulators such as the European Medicines Agency and the FDA have frameworks to provide support on emerging technology platforms. Industry has a partnership with the regulators to provide assurance to patients that medicines are both safe and efficacious. The activities within the quality control testing environment provide some of the elements that support the holistic data package on the suitability of the final product.

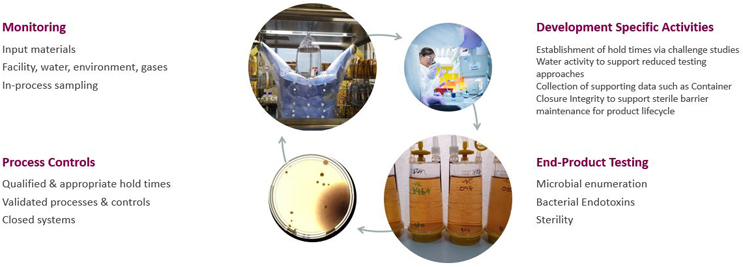

Microbial quality is a critical quality attribute, whether for the appropriate assurance of microbial quality for a non-sterile dosage form or sterility of a parenteral product. However, microbial quality cannot be assured by end product testing alone; a holistic approach is required, considering environmental control, input materials, and the application of validated processes during manufacturing. Refer to Figure 1 for an overview.

Figure 1: A high-level summary overview of microbiological quality control

Technology has advanced, and so too has the pharmaceutical microbiology laboratory. Industry is progressing in the modernization of the microbiology laboratory and, in recent years, this has been shared in publications and conferences around the world.

The Origins Of The Strategy

The vision for the microbiology technology strategy was aligned to meet business drivers across AstraZeneca, considering activities performed by industry peers, regulatory guidance, and an understanding of the variation of the sites within the global network. The aims were to

- increase productivity and understanding

- develop standardized, digitally enabled lean processes

- appropriate use of automation for sample handling and result interpretation

- produce rich data with direct capture

- use sustainable technologies

When initiating a vision for technology transformation, it is important to understand the current state. Working within a global network, it was a key foundation to understand what challenges the laboratories faced, what risks were present, what other technology strategies were being evaluated, and what activities were progressing in linked areas, as well as look at the external landscape and regulatory guidance and explore the development portfolio. Understanding the future needs of the QC laboratory is fundamental in exploring future testing options.

The following activities occurred on a network level, with representatives from each of the different microbiology laboratories present to gain a comprehensive understanding of the landscape:

- Roundtable audit discussions

- What were auditors asking when they visited sites?

- Where were the hot topics?

- Which questions were less straightforward to answer?

- Were there any trends and themes that could be observed?

- Regulatory considerations

- In addition to our internal broad network, the external landscape was also explored, considering publications on microbiology-linked product recalls, the FDA warning letter database, and other published information from regulatory agencies.

- Draft guidance and final versions of publications and review process highlighted areas that may need further attention and the potential to apply technology solutions.

- Learnings from conferences and events, where regulators share updates and hot topics

- Benchmarking of current tests

- Volume of tests and resources allocated to tests

- Types of tests being performed and frequency of those tasks

- Location of test execution (for example, multi-production sites may have satellite laboratories)

- Development portfolio review

- Understanding what products may be in the future microbiology laboratories

- Understanding new approaches to manufacturing and adaptive control strategies

- Application of advanced control strategies in all areas of quality

- Risk assessments of the current state

- Many microbiology laboratory activities are manual and subjective; a cross-site review of the risks associated with these was conducted and used to prioritize areas to standardize

- Risk assessments of current tests and data flows

- Risk assessments of proposed changes

This large volume of information was reviewed and considered and key concepts were pulled out to define areas of the strategy, with a short-, mid-, and long-term plan building on technology approaches that could be taken.

Prioritization was largely based on mitigating risks from the current ways of working. These include risks faced by any microbiology laboratory; the raw data is often the agar plate or the unit of nutrient media and the review of this data is subjective by its very nature and, therefore, application of technologies to reduce subjectivity and optimization of robustness of data integrity were desirable.

A large volume of activities in the microbiology laboratories supporting sterile product manufacturing facilities included environmental monitoring; samples taken of air, surfaces, and personnel undergo incubation, followed by manual reading and review. Data was captured in a variety of systems across the network and then the trending of that valuable data was performed in a variety of ways.

Pharmaceutical water systems is another area where samples are removed and incubated remotely. In all cases, an incubation period leads to a delay in the time available to respond to events.

During the risk assessment activities, to enable the collaboration of multiple sites, a simplified approach was taken. This considered the activity (in the unmitigated state) and how easily a mistake could be made and, if such an error occurred, could it result in patient harm?

Technology Evaluation And Deployment

The following areas were identified as key priorities for a short-term technology uplift plan:

- automation of endotoxin testing of pharmaceutical waters (using microfluidics)

- standardized software for environmental monitoring data capture

- Matrix-assisted laser desorption/ionization time of flight (MALDI-TOF) as a platform for microbial identification

- virtual reality training platforms to uplift laboratory personnel and those working in aseptic processing environments

These technologies were selected for a variety of reasons; in all cases (except the virtual reality training platform), there was extensive experience already within AstraZeneca at one or more sites. Existing data was reviewed and assessed and work packages were built to further understand the technology prior to deployment. In all of these technology evaluations, the technology available both within and outside of the AstraZeneca network was considered, in either paper-based exercises on publications or through additional laboratory verification and validation studies.

For technologies not already present within the network, we developed a framework to evaluate them, which would consider the technology from the feasibility through deployment phases. Broadly speaking, the high-level overview of the process is described below once an activity is prioritized for a technology uplift:

- Evaluation of available technology

- Literature reviews

- Attendance at conferences

- Dialogue with technology providers

- Where possible, dialogue with technology users at peer pharmaceutical companies

- Review of information provided by regulators, in some cases (for example, USP<1223> technology principles are listed)

- Initial feasibility studies

- These may be performed within the AstraZeneca laboratory or at a third party (such as the technology provider).

- The feasibility study will assess if the technology could be capable of delivering a solution for the activity requiring technology uplift. This will consider if any development of the technology will be required for the desired application.

- Proof-of-concept studies

- These may be performed within the AstraZeneca laboratory or at a third party (such as the technology provider).

- For quantitative microbiology techniques, this typically looks at a range of microorganisms at a range of inoculum levels to assess if the technology proves the desired concept.

- For qualitative techniques, low levels of inoculum of a range of microorganisms are used.

- Within proof-of-concept studies, interfering factors, such as product and plant room vibrations, are also considered.

- Verification studies

- Extensive studies that bring in elements of the validation of alternative microbiology methods will be conducted at one site. These are conducted to GMP standards, and the data generated will support the full validation package (this list is reviewed and amended dependant on the technology, the application, and the existing data availability).

- Accuracy

- Specificity

- Linearity studies (for qualitative)

- Establishment of limit of detection

- Range

- Precision

- Robustness

- Ruggedness

- Limit of Quantification

- Equivalency

- Data connectivity

- Working with partners in IT, the data connectivity is established between the technology and laboratory systems. Having standard platforms for data capture and reporting minimizes the complexity of this.

- Extensive studies that bring in elements of the validation of alternative microbiology methods will be conducted at one site. These are conducted to GMP standards, and the data generated will support the full validation package (this list is reviewed and amended dependant on the technology, the application, and the existing data availability).

- Validation studies

- The verification data will be reviewed and final execution of validation studies is performed. This may be conducted in a central laboratory.

- Industrialization

- A technology transfer process is conducted, whereby primary and secondary verification studies are executed. These consider elements of the verification and validation studies previously performed and are executed with a pre-agreed protocol.

- Deployment

- A playbook is created for the technology package that includes the historical evaluations and the final validation packages.

- The playbook will include proposed protocols, which may be executed as is or may require site-specific adjustments.

- Sites are selected to onboard new technologies based on the needs of the sites and are supported centrally to ensure a standardised approach is adopted.

Summary

A successful strategy has clearly defined short- to long-term aims. It is fluid and adaptable. A clear understanding of the current state is required to identify the appropriate technology and applications of technology to be selected. Prioritization is fundamental to success.

Harmonizing the ways multiple sites work enables technology onboarding; for example, a standard data reporting system will simplify the data connectivity in the verification phases.

While change can be challenging within the industry, a clear understanding of the needs a technology can fulfill and the day-to-day activities of the user can facilitate smooth transitions.

With game-changing technologies becoming ever more available, the concept of “better never stops” is here now. Looking to the future, we will continue to uplift and transition. The truly transformational technology that will be used in our future laboratories may not even exist today, which is why it is important to keep moving on the path for technology uplift.

About The Author:

Miriam Guest is an associate principal microbiologist in Pharmaceutical Technology & Development, Operations, AstraZeneca, working in the New Modalities and Parenteral Development group, based at the company’s Macclesfield site in the U.K. She has worked in pharmaceutical development for more than 20 years, in both microbiology and formulation laboratories and GMP manufacturing environments. More recently, she has been supporting complex supply chains and designing robust control strategies, including the associated regulatory authoring and interactions. She leads the AZ Global Microbiology Forum, bringing together the global network of microbiology labs to drive standardization and quality principals in microbiology. Guest devised and leads AstraZeneca’s 21st Century Microbiology Strategy to innovate, industrialize, and implement technology solutions to drive efficiencies and process robustness benefits. She is an active committee member of the Pharmaceutical Microbiology Interest Group (Pharmig) and is involved in various cross-industry consortiums, including BioPhorum and the M3 Collaboration.

Miriam Guest is an associate principal microbiologist in Pharmaceutical Technology & Development, Operations, AstraZeneca, working in the New Modalities and Parenteral Development group, based at the company’s Macclesfield site in the U.K. She has worked in pharmaceutical development for more than 20 years, in both microbiology and formulation laboratories and GMP manufacturing environments. More recently, she has been supporting complex supply chains and designing robust control strategies, including the associated regulatory authoring and interactions. She leads the AZ Global Microbiology Forum, bringing together the global network of microbiology labs to drive standardization and quality principals in microbiology. Guest devised and leads AstraZeneca’s 21st Century Microbiology Strategy to innovate, industrialize, and implement technology solutions to drive efficiencies and process robustness benefits. She is an active committee member of the Pharmaceutical Microbiology Interest Group (Pharmig) and is involved in various cross-industry consortiums, including BioPhorum and the M3 Collaboration.