BASCO Technologies Introduces Filling And Stoppering Machine Type 535 For Syringes

BASCO Technologies introduces its new Filling and Stoppering Machine Type 535 for dosing and closing nested syringes and other nested containers. Ideal for pharmaceutical manufacturers and biotech companies looking to automate and/or validate the filling of products in clinical trials or in development, BASCO's affordable new filling and stoppering machine handles up to 2000 containers per hour. The Type 535 is designed with stainless steel exposed metal surfaces for washdown compatibility.

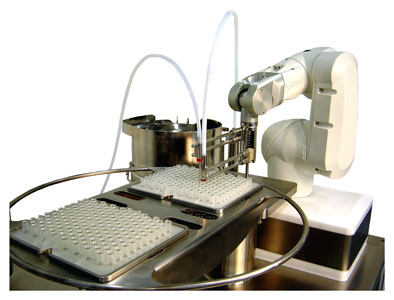

An operator simply loads nests of syringes, vials or other containers onto the infeed table and positions the turntable. The compact system features a cleanroom robot fitted with one set of tooling that handles both vacuum filling and vacuum stopper insertion. The robot automatically positions the vacuum filling and stopper insertion tool for each container. Processed nests are then manually removed.

Using innovative vacuum filling and stoppering technology, BASCO's new machine eliminates product contact with air and reduces operator intervention to assure that the product is not contaminated. BASCO designed its Filling and Stoppering Machine Type 535 with machine guarding that enhances worker safety while providing ample access to the workstations. The machine guarding also supports an optional top-mounted laminar flow unit to improve sterility.

Recommended for use with BASCO's ultra high precision, weld-free, stainless steel, rotary piston pumps, the Filling and Stoppering Machine Type 535 achieves fills ranging from 50 micro liters to 100 ml and maintains fill accuracies of +/- 0.05 percent or better. One operator can easily accomplish a container size changeover in under 15 minutes, no tools required.

SOURCE: BASCO Technologies