BASF provides Nanophase Technologies with $1.3 million equipment loan

Supporting coating processes for BASF products

Nanophase Technologies Corp. (Burr Ridge, IL) will receive a $1.3 million loan from BASF Corp. (Mount Olive, NJ) to purchase and install capital equipment to scale-up a proprietary coating process for nanocrystalline materials to support BASF product development.

Nanophase will install the equipment in its new 37,000 square foot Romeoville, IL facility with an expected operational date of June 2001. The arrangement will allow Nanophase to place the manufacturing operation under its ISO-certified and GMP-registered manufacturing operations as delivery volumes increase over the supply agreement period.

The companies have amended their November 1999 supply agreement to coincide with the new loan agreement. The amended supply agreement terms will now run through June 2004, an increase of approximately 20 months over the initial deal.

"Our close and expanding relationship with BASF, beginning with the original supply agreement announced in November 1999, has demonstrated the positive effect of the business model, implemented last year, to work with customers and provide end-use solutions utilizing nanotechnology," stated Joseph Cross, Nanophase's CEO. "We are obviously delighted with the long-term confidence in Nanophase and its solutions that is evidenced both by BASF's investment in equipment and in its commitment to additional volumes during the next several years. We look forward to continuing to expand our relationship with a world-class leader like BASF."

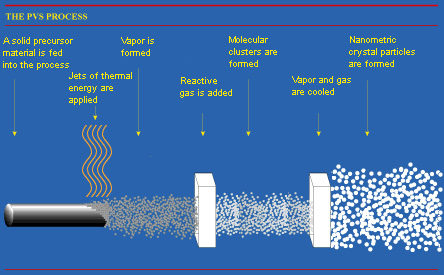

Nanophase uses several techniques to achieve nanoparticle sizing. The company's physical vapor synthesis process, pictured above, uses a plasma to heat a precursor metal. The metal atoms boil off, creating a vapor. A gas is introduced to cool the vapor, which condenses into liquid molecular clusters. As the cooling process continues, the molecular clusters are frozen into solid nanoparticles. The metal atoms in the molecular clusters mix with oxygen atoms, forming oxides, e.g. aluminum oxide, smaller than 100 nanometers in diameter.

For more information: Nanophase Technologies Corp., 1319 Marquette Drive, Romeoville, IL 60446. Tel: 877-653-8100.

Edited by Angelo DePalma

Managing Editor, Pharmaceutical Online and Drug Discovery Online

Email: adepalma@vertical.net