Closed And Semi-Automated Processing Of CAR T Cells

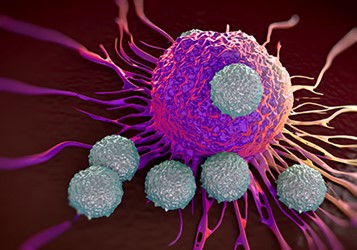

There is considerable excitement surrounding the treatment potential of T cell immunotherapies. Despite the clinical success of chimeric antigen receptor (CAR) T cells, there remain challenges associated with routinely offering these products as treatment alternatives. These challenges include the costly manufacturing process relying on lengthy and complex open workflows with high manual labor requirements that influence product variability.

This article describes the details of a robust CAR T cell manufacturing workflow that can be adapted for current good manufacturing practices (cGMP) compliance in commercial production of CAR T cells. This semi-automated, closed CAR T process achieves 1 × 1010 expanded T cells. Enhanced green fluorescent protein (eGFP) transduction efficiency is greater than 80% across an 8-day manufacturing process.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Pharmaceutical Online? Subscribe today.