CNC Machining Capabilities

Proto Labs’ rapid CNC machining capabilities are subtractive manufacturing processes used ideally for prototyping, form and fit testing, jigs and fixtures, and functional components for end-use applications. The high-speed milling and turning processes are used to create parts from more than thirty different engineering-grade plastic and metal materials.

Rapid CNC Milling

Rapid CNC Milling

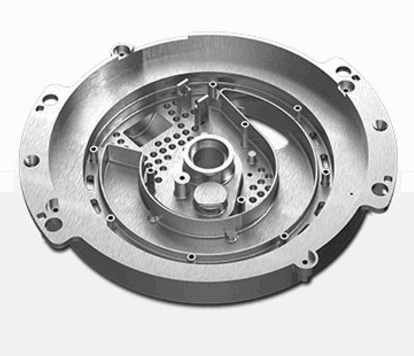

The rapid CNC machining process is used to manufacture custom parts for high-quality prototypes, custom jigs and fixtures, and functional end-use parts. Proto Labs is capable of using 3-axis milling from 6 orthogonal sides and 5-axis indexed milling, which can accommodate complex geometries like off-axis features and non-orthogonal holes. Click here for more information on the CNC milling process, quoting, and design guidelines.

CNC Turning

The CNC turning process is a method where a rod stock is rotated while a tool is held against the stock to remove material and create a cylindrical part. Features such as axial and radial holes, flats, grooves, and slots can be machined using a CNC lathe with live tooling. Proto Labs range of metals, including soft metals and steel, allows parts to be made with the desired material properties. Outside diameter (OD) and inside diameter (ID) threading is also available. Click here for more information on the CNC turning process, quoting, and design guidelines.