Colorcon Adding Three European Labs to Support Demand for Dow's Methocel

Colorcon seeks to strengthen Methocel's position as the leading product for controlled release applications. Like its partner, Dow Chemical (Midland, MI), Colorcon wants to expose potential customers to the benefits of the methylcellulose family of tabletting excipients and liquid dosage form thickeners early in a pharmaceutical product's development. "We want to get involved early in the process and help design drug deliver systems," said Methocel Global Marketing Manager Philip Pilnick. "Colorcon has always had the network of contacts in the industry. Their three new lab sites enable them to service their customers faster and better."

Pilnik did not feel comfortable naming products that use Methocel, but stated that most coated tablets probably use some form of hydroxypropyl methylcellulose (HPMC). That's especially true, Pilnik added, for products using hydrophilic rate-releasing polymers. "Look at PDR and you'll see dozens and dozens of products using HPMC, which is most likely Methocel."

Methocel's claim to fame is a dissolution profile favorable for sustained-release medications.

About Methocel

Cellulose ethers such as Methocel are used to create reliable formulas for tablet coatings, granulation, controlled release, extrusion, molding, and for controlled viscosity in liquid formulations.

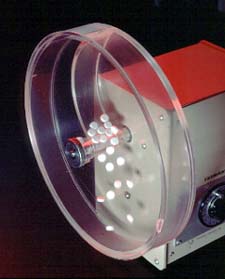

Cellulose ethers form strong films with good adhesion to underlying pharmaceutical materials, providing taste-masking and acting as barriers for water-sensitive drugs or components. Methocel cellulose ethers increase compressive strength and reduce friability yet they increase overall tablet size by only 1–3 mm. Coatings containing cellulose ethers can be applied in one pan, shortening coating time, reducing skilled operator requirements, and permitting the use of automated coating systems. Because cellulose ethers can be used with a wide variety of solvents, they are extremely versatile in wet granulation formulations.

Cellulose ethers make tablets stonger while adding a small fraction to their dimensions.

In hydrophilic matrix systems, Methocel incorporates uniformly throughout the tablet. Upon contact with water, the outer tablet skin is partially hydrated, forming a gel layer. The rate of diffusion of actives out of the gel layer and the rate of erosion determine the overall tablet dissolution and drug delivery rates. Precise and reliable adjustments of these rates are possible because the properties of Methocel have been so well documented.

A very large body of data exists on integrity of tablets coated with Methocel hydroxypropyl methylcellulose.

Methocel can be heated and mixed with plasticizers for extrusion or molding into a wide range of physical forms. Formulators use it to design single-unit matrix tablets, soft gel capsule replacements, and multi-particle delivery systems using extruded beads or shaped chips. Cellulose ethers are excellent thickeners in oral and topical liquids. Because they have surfactant properties, they may also contribute to product stability. In products like antacids, cellulose ethers act as suspension agents.

For more information: Philip Pilnik, Global Marketing Manager, Methocel Cellulose Ethers, Dow Chemical Co., 1650 North Swede Rd., 100 Larkin, Midland, MI 48674. Tel: 517-636-2639.

By Angelo DePalma