Fenwal Safety Systems Introduces Breakthrough Explosion Detection Technology

Fenwal's MEX-3 Explosion Multisensor

Functioning as part of the Fenwal explosion suppression system, the MEX-3 uses algorithmic technology, a dynamic measuring system and decision-making logic, to distinguish between explosions and normal variations in a process conditions. The Fenwal MEX-3, designed for flush mounting with a stainless steel body, features two rugged ceramic pressure-measuring cells, making the detector more resistant to the rigors of industrial environments.

Example: Pulverizing

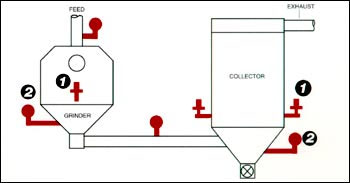

Pulverizing, along with milling and grinding, are heavy-duty operations for reducing the particle size of organic or inorganic materials. Pulverizers typically consist of one or more grinding mills and a dust collection system connected by a pneumatic conveyor. High levels of dust concentrating near the mill outlet can produce violent explosions when suspended in air in a confined volume.

Most often, the pulverizing mill provides the source of ignition as sparks when metal or stone fragments come in contact with mill components. In some cases, material binding on the conveying system causes friction, which results in the material catching fire.

Explosions occurring in pulverizers tend to spread rapidly to other areas. Therefore, proper explosion protection focuses on analyzing the process configuration to fit critical components (mill, dust collector and conveyor) with a system capable of detecting and suppressing explosions in milliseconds.

The Fenwal Explosion Protection System utilizes pressure sensitive detectors with reliable high-rate-discharge extinguishers to suppress an explosion should it occur. Custom-designed Fenwal Systems currently are guarding hundreds of pulverizing processes in all types of industries and environments. Their documented history of successful suppressions is being added to each year.

How it Works

- Strategically-placed detectors sense changes in pressure caused by an impending explosion.

- In 3 to 5 milliseconds, high-rate-discharge (HRD) extinguishers begin to deliver an explosion suppressant to the protected area, supressing the explosion's fireball.

- Control unit provides both alarm outputs and process interlocks.

Fenwal Safety Systems, a division of Kidde Technologies Inc., serves the aerospace, defense, food processing, grain, chemical, pharmaceutical, and petrochemical industries. Fenwal is headquartered in Marlborough, MA and provides its systems and services worldwide.

Visit Fenwal at Interphex, booth 1549.

For more information: Clive Nixon, Fenwal Safety Systems, 700 Nickerson Rd., Marlborough, MA 01752. Tel: 508-481-5800. Fax: 508-485-3115.