GE Fanuc Introduces Open Architecture Process Control System

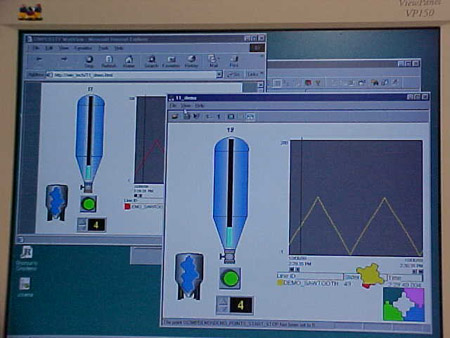

OpenProcess provides distributed control system (DCS) functionality to design, implement, document, and maintain process control systems. According to Cimplicity marketing manager Ralph Rio, it combines "the best of traditional distributed control systems with the efficiency and ease of open systems in a single integrated product."

Older systems, Rio continues, require users to program HMIs and programmable logic controllers (PLCs) separately. In OpenProcess, users program PLC and DCS units in a single step through the Cimplicity HMI.

Engineers program the HMI using intelligent SAMA-style control schematics that include more than 60 function blocks. These include cascaded PID; two and three-state digital control; sequencing; and feed forward, ratio, and balance demand. The system automatically documents generates design documents, bills of materials, wiring schematics, and operator interfaces. The self-documenting nature of the program reduces life-cycle costs by up to 40%, says Rio.

Rio says the system is a good solution for small-to-midsize chemical producers and formulators. It is capable of handling 50-100 loops and up to 500 I/O's. Rio expects it to compete with the lower end of Fisher-Rosemount Systems' DeltaV offering. It also competes in the same market as Moore Process Automation's Procidia.

He also expects to score among companies whose operations combine chemical processing with such mechanical operations as fabrication, assembly, painting, and packaging. A pharmaceutical maker, for example, might want to blend and compound chemicals to make medicine, then count, bottle, and pack the resulting product. Semiconductor manufacturers typically use chemical and robotic fabrication to make chips. GE Fanuc has an advantage in this market, since it can supply a complete Cimplicity solution to handle both sides of the business.

The company began beta-testing OpenProcess in June at food processing and power generation facilities. "They liked the integrated programming," says Rio. "We've also priced it right for small companies. A small system, including a Cimplicity HMI and OpenProcess controller, could sell for as little as $20,000 plus the labor needed to integrate the system into the plant. The company has already sold four systems.

Users have several controller options. GE Fanuc's PA-30 handles up to 100 loops in 350 ms and provides Profibus and DeviceNet connectivity. PA-70 also handles 100 loops, but at 60 ms, while PA-70H offers a hot standby solution for critical control applications. Cimplicity also supports GE Fanuc's Genius I/O blocks, which provide remote diagnostics.

The company says OpenProcess makes it easy to create point databases, develop control strategies, and produce graphical user interfaces. The system's commissioning, maintenance, and reporting tools simplify acceptance testing. They also permit on-the-fly configuration during testing, startup, operation, and maintenance.

Among other key OpenProcess features:

- Ease of learning. The program closely follows Microsoft protocols. "If you know how to use Microsoft Powerpoint, you already know 80% of OpenProcess," says Rio.

- Support of pictures and movie clips. At least on OpenProcess user has taken pictures of his plant and linked the pictures to process alarms. When an alarm goes off, a picture of the affected area automatically pops up on the screen. This slashes the time maintenance technicians need to identify where they have to go. OpenProcess also supports short movie clips ("avi" format) showing service or other sequences, as well as live on-site inputs from still or video cameras.

- Web publishing. A single click is all it takes to publish plant information on the Web. (Rio advises clients to do this on a secure server.) This supports remote monitoring (such as customer inventories). It also allows on-call engineers to tap information about problems from remote locations.

- Advanced control strategy configuration. OpenProcess permits graphical function block diagram programming with an integrated AutoCAD editor.

For more information: Ralph Rio, Manager, Cimplicity Marketing, GE Fanuc Automation North America Inc., 1 Columbia Cir., Albany, NY 12203-5189. Tel: 518-464-4541. Fax: 518-464-4613.

By Alan S. Brown