Glass Vial Systems

Stevanato Group produces glass vials from Type I glass tube in different sizes and capacities, in bulk or ready-to-fill configuration. With full control over geometry and surface chemistry, our vials can be tailored to meet the different needs of biopharmaceutical customers.

Our portfolio also includes special vial containment solutions as microvials for respiratory and sublingual applications, and low delamination propensity vials (LDP) for aggressive compounds.

Stevanato Group is certified ISO 9001 and ISO 15378 and Type I glass tube used for vial production comply with PH.Eur., USP and JP.

We can produce a whole range of rings, starting from the standard inner lip to special blow back designs for specific applications. This feature is available for all the collar designs including standard collar, sealing bead, screw neck and more.

Beyond dimensions and design, our glass vials can be customized with special features like:

Nexa® Vial System

Nexa® Vial System

As drug complexity increases, primary packaging suppliers must develop new approaches to increase stability between drug and its containment solution in order to ensure the best drug administration. Superior cosmetic appearance is no longer desirable but essential.

In response to these market demands, Stevanato Group has developed Nexa® Vials. These state-of-the-art containers provide the highest level of quality, safety, and technology - even for the most demanding drugs.

Benefits

- Superior cosmetic performance, reducing false rejection rate

- Proprietary 100% camera inspection

- Quality improved process platform for forming, transporting and handling

- Limited Glass-to-Glass and glass-to-metal contact to reduce flaws: increased mechanical resistance

- Dedicated DEL with reduced AQL

- Dedicated alveolar packaging

Preferred market choice

- Biologics

- High value vaccines

- Cytotoxic

- Next gen drugs

Fina® Vial System

Fina® Vial System

Fina® is the answer for those searching for a higher-quality level product in comparison to market standards. Fina® allows a great degree of customization in terms of geometry, dimension, and tolerances.

Benefits

- Higher operational efficiency during Pharma filling operations

- Improved cosmetic quality: Reduced AQL for critical defects

- Wide range of sizes, components, produced according to high-standards.

- Customization upon request

Preferred Market Choice

- Vaccines

- Antibiotics

- Generics

Targeting different needs of the Biopharmaceutical industry with EZ-fill®

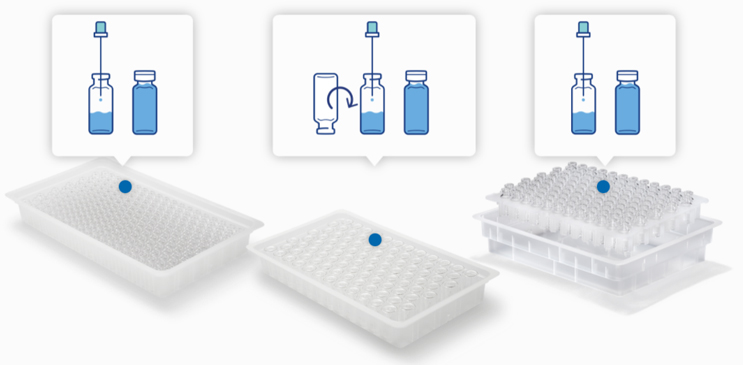

The EZ-fill® pre-sterilized containment platform has been developed in close collaboration with equipment manufacturers to respond to the need to increase operational flexibility.

Thanks to the unique layout of the secondary packaging, EZ-fill® maximizes filling efficiency by allowing different combinations of filling nozzles. From incoming material to final product shipment, every aspect of the filling process can be streamlined with EZ-fill®.

How do I fill it? We have got you covered with EZ-fill®

Add-on components

A rubber stopper and an aluminum cap typically comprise a vial closure system. Depending on the application and fill-finish process, the stoppers and caps vary in sizes, formulation, and design.

Based on its extensive knowledge of container closure systems, Stevanato Group can help biopharma companies and device manufacturers mitigate risks associated with the containment solution selection.

Working with the best-in-class manufacturers and an expert team, Stevanato Group is able to determine and supply the adequate solution.

Add-on Specifications

Rubber Stoppers

- 13 mm – 32 mm

- Lyo / Serum

- Chlorobutyl / Bromobutyl / others (special applications)

- Coated / Non-coated

- RfS / RtU

Aluminum Caps

- 13 mm – 32 mm

- Only aluminum

- Diverse opening capabilities

- Aluminum + Plastic

- Different opening designs

- Personalized colors available