Honeywell Introduces Advanced Plant Control Network for Its TPS System

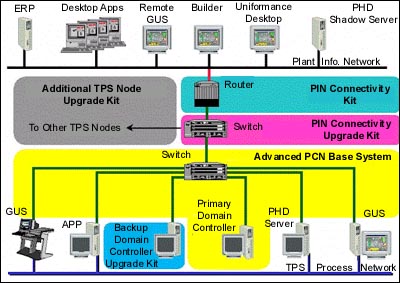

The TPS system's Plant Control Network links nodes delivering advanced application, human interface, historian, and information capabilities in a secure Windows NT environment. The network also enables unification of the process control and information domains for better decision making and improved plant operations.

The Advanced Plant Control Network joins Honeywell's recently introduced Packaged Plant Control Network (PPCN) to form a family of structured packaged PCN products that address different levels of market requirements. APCN offers all the advantages of PPCN plus the following features:

- Multiple locations—APCN supports TPS nodes installed in up to three locations in the same or different buildings.

- Higher reliability and availability—APCN can provide redundant switches at each location and uses server-grade platforms for both Primary and Backup Domain Controllers.

- Greater expandability—APCN can support up to 60 nodes.

- PIN connectivity—APCN optionally provides a router and the installation and configuration services needed to link the Plant Control Network and the business LAN or plant information network (PIN).

- Broad choice of network hardware—APCN gives users the choice of using network products from Nortel, 3-Com, Cisco, or Fore System.

Users can take advantage of APCN's flexible design to meet company- or site-specific security and environmental requirements. This engineered solution helps reduce the Total Cost of Ownership by providing complete project installation services to speed overall project implementation.

APCN consists of a 10/100BaseT-TX Ethernet Local Area Network (LAN) and a Primary Domain Controller (PDC) on a server-grade platform with a redundant array of inexpensive disk (RAID) storage sub-system. The package also includes fiber-optic and unshielded twisted pair (UTP) patch cords, and complete installation and configuration services. Additional switches and Backup Domain Controllers (BDCs) can be added to further enhance network reliability and robustness. A complete suite of fault, performance, and systems management services are also offered.

APCN provides a complete network for TPS users who are implementing HCI/OPC-based open control solutions. The Advanced PCN provides a truly open and vendor-neutral solution to the user's plant connectivity requirements.

Open Networking

APCN is part of Honeywell's move from a mostly proprietary control network system to a standards-based, open network environment. APCN is based on a robust, reliable, process industry-worthy implementation of IEEE's 802.3 Ethernet standard. Hardware and operating software also are based on open platforms.

Honeywell has chosen Compaq server-grade hardware as the "brains" of APCN, and Microsoft NT as the operating system. Customers have a broad choice of network hardware including state-of-the-art switching products from Fore Systems, 3Com, Nortel Networks, and Cisco.

According to Chris Johnston, Network Solutions Manager at Honeywell Industrial Control, Honeywell selected a switch-based architecture because it is capable of moving packets at "wire speed," which greatly reduces latency and improves response times. "The open network layer completely opens up our distributed control environment, while protecting our customer's current investment," Johnston said. "This move is in keeping with Honeywell's Consistent Evolution philosophy and is intended to maximize the total value of ownership of the Honeywell control solution."

"We've been implementing Plant Control Networks for four to five years now, mostly on a 'project' basis," Johnston told Pharmaceutical Online. "Custom-building a network is still probably the best approach for many large customers, but those installing a limited number of nodes, for example, need something that's inexpensive and easy to deploy. With this product we've eliminated most of the design requirements by predesigning some network functions. You lose a bit of flexibiltiy, but we think the benefits of fast deployment and lower cost make up for it."

For more information: Chris Johnston, Network Solutions Manager, Honeywell Industrial Control, Network Technology Group, 2500 West Union Hills, Phoenix, AZ 85027. Tel: 602-313-6342. Fax: 602-313-4173.

By Angelo DePalma