How To Take Your Process To A Closed System

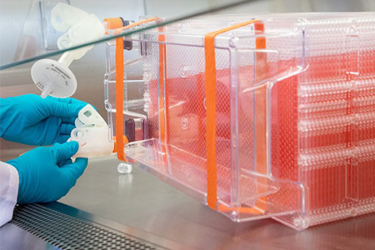

Scaling up production for cell and gene therapies from research to commercial levels presents significant challenges, including contamination risks, high costs, and complex workflows. Open systems, which require frequent human intervention, increase the risk of contamination and can lead to costly delays or product loss. Closed systems provide a solution by minimizing contamination risks, streamlining workflows, and enabling scalable manufacturing processes.

These systems allow scientists to perform critical steps, such as cell seeding, media exchange, and harvesting, with reduced reliance on biosafety cabinets. Additionally, closed systems can be customized to meet specific workflow needs, offering flexibility for labs transitioning from small-scale research to large-scale production. From advanced multi-layer vessels to perfusion-based systems, closed systems are revolutionizing bioproduction for cell and gene therapies.

Explore the benefits, considerations, and innovative technologies behind closed systems. Access the full white paper to learn how these solutions can optimize your manufacturing process.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Pharmaceutical Online? Subscribe today.