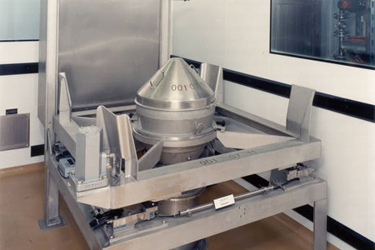

IBC Container Discharge Station

Source: ILC Dover

The DOSICON discharge station has been developed and patented by JetSolutions SA for discharging the DOSICON containers (IBC).

The DOSICON station offers following features:

- Dust free discharge of the container

- Dosing of the discharge of the IBC, for example when a batch is made out of various powders stored in other IBCs

- Weighing of the discharged quantity of an IBC, either by loss in weight or by gain in weight

- Easy extraction of the powder stored in DOSICON IBC, even compacted

- Guarantee of a proof closing of the IBC cone valve

- Cleaning of the inside of the IBC with a CIP system

Working Principle:

- The cone valve is placed and guided at the bottom of the DOSICON container

- The cone of the discharge station lifts and open the cone valve of the container to start discharging

- Total proof connection of the container to the station by means of a lip gasket on the discharge station

- Opening of the cone valve by means of a pneumatic cylinder jack

- Adjustable opening by setting the stroke of the jack (basic version)

- Full range adjustable opening by means of a pneumatic motor adjusting the stroke of the jack (dosing version)

- Dosing of the discharged product by adjustment of the opening of the cone valve versus the weight on scale, through an interface terminal IT 9000

- Vibration of the cone in open position

- Total proof closing by pulling down the cone valve into its seat after discharge of the product