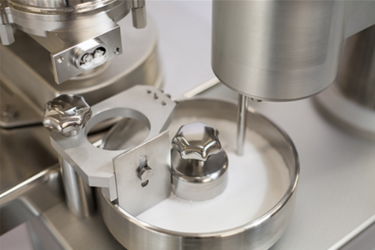

Laboratory Powder Dispensing System: Dosator

This dosator is part of 3P innovation’s Pharma Equipment Discover Range, which fully replicates commercial dosator based powder dispensing, at a laboratory scale.

Using the dosator, pharmaceutical powder formulations can be screened for suitability with commercial machinery. It also automatically produces representative early phase clinical supplies.

The system can be configured to replicate the full range of dosators sizes (with or without pre-compression). When compared with manual filling with spatulas, the introduction of automation into laboratory applications reduces variability and enhances product quality.

- Reduce time to market and process uncertainty

- Lower clinical sample cost

Providing Flexibility

As a laboratory scale device, the dosator fits within small fume enclosures and operates with a very small powder bed. This is critical in the early stages of formulation and process development, when active ingredients may be scarce.

The micro-dosing head version is configured to present consistent powder samples in the 1mg to 5mg range. Where this dosator offers significant advantage is through its inherent flexibility and ability to replicate commercial processes. It can fill medical devices, inhalers, capsules or blisters under controlled laboratory conditions. The system dispenses consistent samples directly into delivery units for clinical or pharmaceutical evaluation.

Further optional enhancements include provision of bulk powder feeds to remove the need for manual powder bowl top-up, and integrated weighing head for 100% recording of all dispensed sample weights.

Supporting Quality by Design

Process understanding and Quality by Design relies on reliable process data. The Dosator provides users with live charting and recording of all critical process parameters. This includes pin height, powder bed height, pre-compression force, compression force and ejection force. Dose weight is also available via an optional high-speed weigh cell.

Reducing time to market and process uncertainty

Understanding uncertainty and minimizing risk early is key to reducing time to market. The Dosator ensures that scale issues are minimized by being compatible with industry standard dosating pin and tube sets. This ensures optimized product handling parameters can be developed from the outset and in the knowledge that the same parameters can then be applied to a scaled-up commercial manufacturing process.

Lowering clinical sample cost

The cost of supplying small-scale clinical trials can be significant because the volumes do not justify commercial production processes. Alternatively, manual filling of capsules, blisters or tablet presses is not a cost-effective use of laboratory staff. The dosator offers a cost-effective alternative. It can dispense powder precisely time after time, decreasing viability, lowering sample-making costs and increasing the throughput of candidate drugs.