Modularity And Mobility Hold The Keys To Surge Manufacturing

By Kayla Hannon, manager of process engineering, TFF Pharmaceuticals

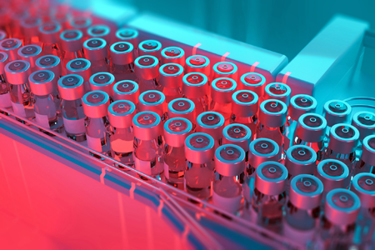

At the beginning of the COVID-19 pandemic, the pharmaceutical industry worked at rapid speed to roll out vaccines. Demand surpassed supply chain capacity and outsourcing dominated as an option for companies to progress their products faster and more cost efficiently, especially for innovative technology that required more specialized expertise. To better meet the demands for rapid development of drugs and the rise of more complicated modalities like biologics, the manufacturing process must become more streamlined. Lessons and practices learned during the use of surge manufacturing could help better prepare the industry for future outbreaks and pandemics.

What Is Surge Manufacturing?

Surge manufacturing is a rapid scale-up and manufacturing effort to prepare a drug stockpile, for example in response to a pandemic, which the government may require. Dramatic production increases may be temporary as the treatment or vaccine may eventually peak and fade. In previous typical production, a normal scale-up would be more focused on increasing production over time to meet increasing demand rather than on speed to meet an immediate large demand. Historically, the time to scale to full production would take years. The need for surge manufacturing developed at the start of the COVID-19 pandemic, when the world needed novel vaccines immediately at an unprecedented high demand. With large backing from the U.S. government to support the most rapid scale-up for a global vaccine, surge manufacturing proved itself as the best way to set up production for healthcare success.

Even with substantial government support, rapid scale-up had limitations and challenges when looking at different facilities and equipment processes to determine which would be the fastest approach to support surge manufacturing. Traditionally, facilities use permanent and purpose-built equipment, which makes it difficult to scale up or repurpose when demand changes. On the other hand, the surge manufacturing model relies on modular equipment and facilities that can pivot to different manufacturing needs and demands.

Modular Design And Single-Use Technology

Process equipment designed to be modular, multipurpose, and single-use all help with rapid mobilization and scale-up when a global crisis or other sudden demand calls for surge manufacturing. Modular equipment design allows equipment to be moved between processing rooms and to be repositioned to change processing trains for different volumes and product formulations.

Along with the modular equipment, flexible cleanrooms allow teams to pivot for new products. Multiple cleanrooms need to be equipped with the core good manufacturing practice (GMP) utilities (e.g., process gases, water for injection, process chilled water, 120V and 480V electrical connections, etc.). Initially setting up a facility to be ready to pivot and handle multiple production trains and different processes will allow for rapid mobilization when surge manufacturing is required.

Single-use technology has a large benefit for rapid mobilization in surge manufacturing. It eliminates or limits the need for cleaning validation, a large GMP utility, and clean-in-place (CIP) and steam-in-place (SIP) systems. Without CIPs and SIPs, you eliminate both the build and qualification of the utility system. You also decrease turnover time to release a piece of equipment by omitting cleaning validation studies and cycle development. Not only does it cut down time, but it allows for the capability of validating the equipment across multiple drug platforms with limited to no risk of cross contamination.

Scaling Up With Process Trains

Traditionally, scale-up of equipment meant scaling the processing volume for a full equipment line. This approach comes with substantially longer design considerations and approvals to go from a clinical scale to a commercial scale. Being able to scale in terms of multiple process trains and cleanroom trains offers a huge benefit for rapid equipment design, build, commissioning, and qualification. This approach allows for process train equipment design to take place once and repeat as more-of-kind equipment fabrication to meet surge manufacturing demand. This approach has been shown to be more cost-effective by cutting down on engineering design as companies scale, and it allows for repeatable functional and qualification test scripts. Streamlining functional acceptance test and commissioning, qualification, and validation (CQV) documents is beneficial from a development and execution standpoint.

Apart from a quicker build and release on the multiple trains, the automation and human interface also stay the same, allowing streamlining of the bill of materials, consumables, standard operating procedures, maintenance and calibration plans, and operator training. Having these documents already in place for released process trains makes getting each subsequent train online quicker and more efficiently. For example, if you split a 100-L batch between three lines, you can contain the processing time in the same shift. The use of multiple process trains also interests contract development and manufacturing organizations (CDMOs) as the mobilization, installation, and CQV documents and activities are already in place, creating an easy transition to scale-up and subsequent repurposing, if applicable.

Whatever Comes Next, Surge Manufacturing Will Rely On Modular Design

Once demand tapers off, modular equipment and use of scaled trains allows for quick redesign and manufacturing for other processes. For example, if you add four trains to scale up quickly from 20 L to 100 L, the trains can be decommissioned and requalified when demand ends for other processing uses at a small scale (clinical) batch size. The ability to pivot from a surge manufacturing demand to a specialty product by repurposing equipment is a huge benefit as the pipeline changes and allows for further use of the train. TFF Pharmaceuticals works with numerous collaborators and CDMOs, all with various approaches, and as such we have moved from benchtop “semi-permanent” setups to mobile equipment, which can easily be rolled into a facility and installed with minimal facility modification, allowing us to manufacture according to each partner’s modality.

While we don’t know what the next global healthcare crisis will bring, we see a trend of increased use of complicated biologics in drug development. To facilitate a more rapid scale-up of specialty modalities during high demand requiring surge manufacturing, modular and mobile equipment offers considerable flexibility that is both cost- and time-efficient.

About The Author:

Kayla Hannon is manager of process engineering at TFF Pharmaceuticals and works with the internal process development team and CDMOs. She has years of experience in sterile pharmaceutical manufacturing as a process, validation, and facilities engineer. Previously, Hannon was a consultant concentrating in commissioning, qualification, and validation activities. She was also previously at Moderna assisting production scale-up and working with CMOs to optimize worldwide production of the COVID-19 vaccine. She holds a B.S honors degree in chemical engineering from Drexel University.

Kayla Hannon is manager of process engineering at TFF Pharmaceuticals and works with the internal process development team and CDMOs. She has years of experience in sterile pharmaceutical manufacturing as a process, validation, and facilities engineer. Previously, Hannon was a consultant concentrating in commissioning, qualification, and validation activities. She was also previously at Moderna assisting production scale-up and working with CMOs to optimize worldwide production of the COVID-19 vaccine. She holds a B.S honors degree in chemical engineering from Drexel University.