New High Heat Flux Process Reactors at Interphex

Zerem's new reactors significantly reduce process batch times while increasing product quality by controlling radial and axial temperature gradients to less than 2ºC. System capacities from 50 to 3000 gallons are available for R & D, pilot plant, and bulk manufacturing processes requiring exothermic or endothermic reactions ranging from low (below -100ºC) to high temperatures.

High performance is achieved by using a cryogenic fluid as a heat sink in a heat transfer device with specially designed geometry, resulting in improved safety, higher product quality and yields. Innovative vessel designs and fluid circuiting permit low batch production (10-15%) and facilitate scale-up of pharmaceutical pilot processes to bulk production. Reactors can be integrated with optional Zero Emission VOC Management system.

Zerem's HHF reactors have the following operating characteristics:

- Radial temperature gradients less than 2º C

- Axial temperature gradients less than 2º C

- 150 kW < Q< 500 kW

- 300 Kg/m3-hr < < 1000 Kg/m3-hr

- kW/m2 < Q/A < 50 kW/m2

- Operating temperatures from –200º C up to +300º C

Where:

Q= heat transfer rate (exothermic or endothermic) = kW

= Space - Time Yield =Reactor product (Kg)/ [Reactor Volume (m3)-time (hr.)]

Q/A= heat flux = kW/m2

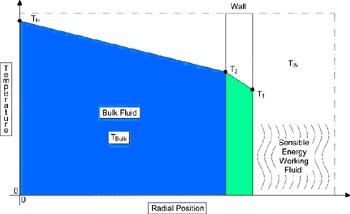

In conventional reactors

- TH-T2> 10º C (large radial thermal gradients)

- Tbulk-TIN< 50º C (modest driving forces)

- TIN approaches Tbul in a single pass of the reactor cooling circuit (driving force decreases)

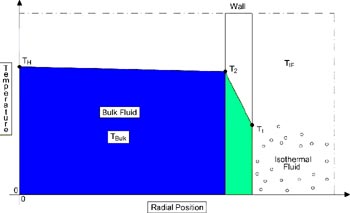

In Zerem HHF reactors:

- TH-T2< 2º C (small radial thermal gradients)

- 100º C

- TIF remains constant and never approaches Tbul in a single pass of the reactor cooling circuit (driving force remains constant)

Practical Results

The Zerem HHF reactor:

- Safely handles exothermic reactions which will be at risk of "runaway" (consequence of high heat flux [Q/A] capabilities);

- Result in more uniform and purer products and higher yields (consequence of low radial thermal gradients)

- Affords shorter production times (consequence of high space-time yield []);

- Incorporate Integral VOC emissions abatement technology, resulting in reduction of entrained VOC emissions to less than 1 mg/m3

Zerem has licensed the reactors for high heat flux applications from Jose Arencibia, a chemical and mechanical engineer who heads Arencibia Associates (Center Valley, PA). Kramer and Arencibia will deliver a paper, "Using Cryogenic Fluids to Manage Pharmaceutical Reactions," on Tusday, March 22, at 2:30. Both men will also hold separate luncheon roundtables: Kramer on the high heat flux reactors, and Arencibia on VOC remediation.

For more information: Charles Kramer, President, Zerem, PO Box 800, Valley Forge, PA 19482. Tel: 610-933-8970. Fax: 610-933-3016.

Angelo DePalma