New Web Site Enables Manufacturing, Formulation Collaboration

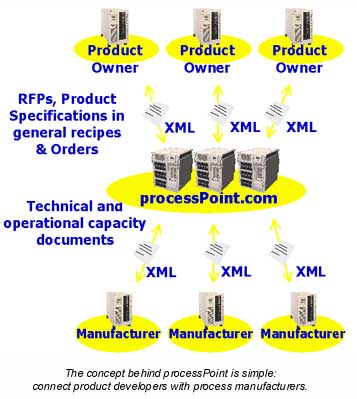

The new products are designed to work with the company's just-launched processPoint website, which helps companies collaborate and buy and sell process manufacturing capability over the Internet. By simplifying outsourcing, companies can reformulate more rapidly, speed new products to market, and extend existing capacity.

gRecipe

The company's new gRecipe software enables companies to create and manage product manufacturing definitions throughout the supply chain in the form of general recipes.

Sequencia says the software has the unique ability to automatically transform its generalized recipes into specific manufacturing instructions targeted to multiple manufacturing locations. The result, it says, is improved product collaboration.

Sequencia likes gRecipe to a CAD file, in that it provides a common means to define and describe a process product. Based on international standards, gRecipe allows companies to specify product chemistry, physics, and manufacturing requirements without defining the manufacturing equipment.

"It is the only system that provides a single solution to create, manage, and deploy a comprehensive process product definition including formula, recipe, equipment, work instruction, and bill of material information," says Sequencia chief technology officer Michael Saucier.

The software follows international standards. Sequencia says gRecipe is the only commercially available product to implement the ISA S88.01 standard's concept of general recipes, which provides for consistent and unambiguous product definitions at the corporate level. This drastically shortens the time required to reach full volume production. New products or existing product updates can be in production in hours, instead of weeks or months.

Companies can deploy gRecipe at a centralized process science or formulation department. It allows them to quickly determine where a product can be manufactured (including the outsourced manufacturing facilities). They can then send recipes generated by with the program through the virtual supply chain over processPoint.

For example, says Sequencia, a process or formulation engineer can create a product definition. gRecipe automatically transforms it into control recipes that open and shut valves in multiple plants across the globe. The general recipe applies to toll, affiliated, contractor, and captive plants. This ensures consistent product quality regardless of manufacturing site, enabling rapid global deployment of new products.

As a result, says Sequencia, gRecipe significantly reduces the load of information collaborative manufacturers must manage. A typical company with 1,000 products may have over 30,000 production recipes. gRecipe can reduce managed information by over 90%.

processPoint

Sequencia also announced the release of two data schemas that make it easier to exchange information about product formulation and process plant equipment on the site.

The schemas provide a structure for data that enables companies to search for specific manufacturing capabilities and share formulations. They follow the ISA S88.02 production recipe standard and IEC 61512 standards for use with other recipe execution systems. By defining data structure and meaning, they let companies share information even though they use different software programs and operating systems.

Based on the Microsoft BizTalk Framework, the schemas use Extensible Makeup Language (XML) messages to adapt existing data models, solutions, and application infrastructure for electronic commerce. The approach allows specialty chemical, pharmaceutical, food and beverage, and consumer packaged goods manufacturers to broadcast site capabilities, and permits product owners to share recipes and formulations which chosen manufacturers.

"Until now," says Saucier, "matching and exchanging highly complex and detailed information between companies or plants hasn't been technologically feasible without significant customized engineering effort. Our expertise in recipe management presented a unique insight for developing these XML schemas.

"Now, process industry companies can enjoy the efficiency and profitability advantages of outsourced manufacturing employed by semiconductor and electronics manufacturers," he says.

For more information: Sequencia Corp., 15458B N. 28th Ave., Phoenix, AZ 85053. Tel: 602-896-3700. Fax: 602-896-3896.

By Alan S. Brown