Optimizing And Intensifying ADC Aggregate Removal: A DoE Approach To Membrane Chromatography And Rapid Cycling

By Geoffrey Pressac and Timo Schmidberger

Historically, chromatography resins have been the mode of choice for downstream purification in bioprocesses. Despite their widespread use in the industry, these resins are limited by low flow rates, resulting in low productivity. Additionally, resins are expensive and involve non-value-added tasks such as column packing and cleaning. In contrast, chromatography membranes have larger pores that support convective mass transport with a tenfold increase in process flow rates compared to resin-packed columns, making them a viable alternative. This high productivity can enable a rapid-cycling chromatography approach that further reduces footprint. Moreover, single-use membrane adsorbers mitigate the risk of cross-contamination while optimizing facility resources.

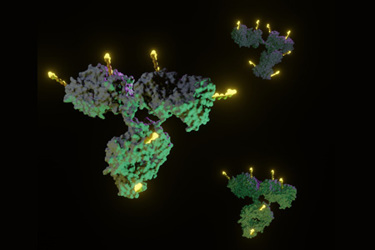

Within the oncology field, antibody-drug conjugates (ADCs) represent a growing therapeutic segment. ADCs combine highly potent small-molecule payloads with mAbs to improve their specificity as a cancer treatment. The conjugation process typically promotes the formation of aggregates and undesired drug-to-antibody ratio species that must be removed by following purification steps. This study investigates the feasibility of employing single-use chromatography membrane technology as a substitute for resin-based chromatography in the ADC process.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Pharmaceutical Online? Subscribe today.