Overcome Lyophilization Challenges During Development, Scale‑Up And Manufacturing Of Biologic Products

By Zak Yusoff, Pharmaceutical Freeze Drying Applications, Manager, SP Industries, USA

Due to their complexity and characteristics, there are many challenges associated with development, manufacturing and distribution of biological products. Stabilization by lyophilization is attractive to retain the product’s biological activity, structural integrity and homogenous quality, all of which are crucial to the success of the product. Each part of the freeze-drying process has a large impact on product quality and integrity.

With the advance of technologies and more sophisticated tools, there is a better understanding of how to measure and record parameters that affect the final product and therefore, greater knowledge of the product itself. This shift from a trial-and-error approach to a science-based approach for the lyophilization process provides confidence of in vivo product performance of these biologic drugs.

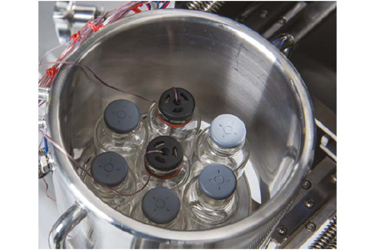

This white paper describes the challenges associated with lyophilization of biologic drug products. Using a Quality by Design (QbD) approach with the SP Line of Sight™ (LoS) suite of technologies that provide a data-rich environment, many of these challenges can be overcome. In particular, scaling-up of lyophilization from early development to full commercialization can be streamlined through the use of scalable technologies available within the LoS portfolio. Companies working on biologics need robust processes with proven data to deliver successful products.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Pharmaceutical Online? Subscribe today.