Overseal Capping Systems For Vials And Infusion Bottles

Source: Syntegon Pharma Technology Inc.

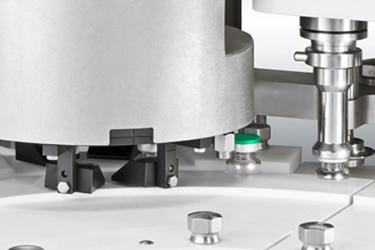

At Syntegon, the development and production of sealing machines for vials and infusion bottles has a long tradition. The low-particle crimping method, in which the container is released from the transport system during crimping, became a trendsetter for modern, pharmaceutical production.

Syntegon continues the tradition with the VRT 1010/1020, and offers a sealing solution that satisfies modern technical production requirements as per Annex 1 of the EU GMP Directives. Its design and used materials make the VRT 1010/1020 suitable for use both in and outside the sterile area. It also offers the best conditions for barrier system operations as for example RABS or isolator.

Benefits:

- Low-particle crimping method

- Ideal for usage inside isolators

- Wash-Down possibility

- Annex 1 compliant: Control of stopper position with discharge prior to the overseal capping station

- Flexible integration into production lines

- Wide processing range of different container types

Options:

- Left-side and right-side version

- Different infeed and outfeed versions

- Combination with barrier systems (RABS, cRABS, Isolator)

- Cap supply system

- Integrated inspection systems for stopper seat control possible

- Magazining station, 2-track

- Particle and germination monitoring

- Bad discharge before and/or after the crimping station