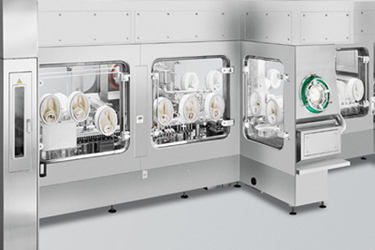

Pharmaceutical Filling And Closing System For Pre-Filled Syringes: FLS 3000

The FLS 3000 is a trendsetter, designed with leading edge technology for the filling of bulk syringes.

The FLS has a precise, continuous and Laminar Flow suited conveying system without additional centering and with only a small number of transitions. The syringe barrels are clipped into the conveyor system with the opening pointing up. The length of the machine and/or the conveyor system is variable.

The syringe barrels are fed with a segmented star wheel with intermittent motion. Syringes may be fed via the optional Pharma Handling Unit HU 160 to the conveying system.

The number of the filling and closure stations is variable from 2 to 6 stations. Pre- and post-gas flushing take place separately, gas flushing during filling and closing is integrated into the appropriate stations. The FLS can be equipped with any of the well-known and successful filling systems of Syntegon: time-pressure filling system, rotary slide valve pumps, peristaltic pump, mass flow system and rolling diaphragm pumps.

Benefits:

- Slim, user-friendly design

- Perfect for isolator technology

- All movements are servo-controlled

- Large size range up to Ø30 mm

- Easy and fast size changeover by means of push-fit size parts

Options:

- Pharma Handling Unit HU 160

- IPC (fully automatic in-process control system)

- Gas flushing before and after filling

- CIP / SIP

- Vacuum stoppering with CIP/SIP of the vacuum route for maximum pharmaceutical security