Pharmacon™ Downflow Booth Generation 3

Esco Pharma's Downflow Booth Generation 3 (DFBG3) is a new generation of Esco powder containment booth which provides simplicity with assured quality.

The Downflow booth is used for non-aseptic, opening sytem ambience booth and ensures operator and process protection using HEPA-filtered laminar downflow air to prevent the powders deposit to the operator breathing zone via the negative pressure principle during open handling processes such as weighing, dispensing and sampling. With various configurations provided, DFBG3 adapts to your specific needs with fully customizable options. Its flexible design suits a wide range of applications across various industries.

Pharmacon™ DFBG3 Applications

- Pharmaceutical

- Cosmetic

- Nutraceutical

- Food

- Electronic

Features

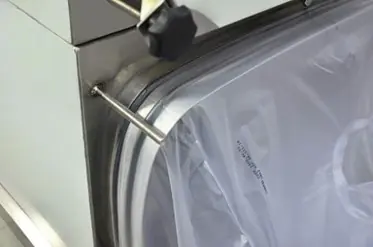

Standard Safe Change Filter version

The backstack is specifically designed for the Safe Change Filter of the Air Return filter(s). This will suit your potent/hazardous powder handling.

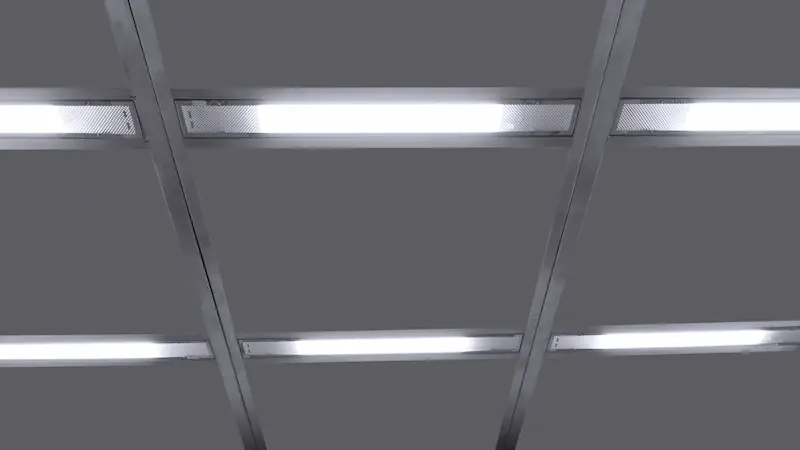

Enhanced flush mounted design

This is equipped with lighting and local operating panel flush mounted design to provide a smooth surface of ceiling.

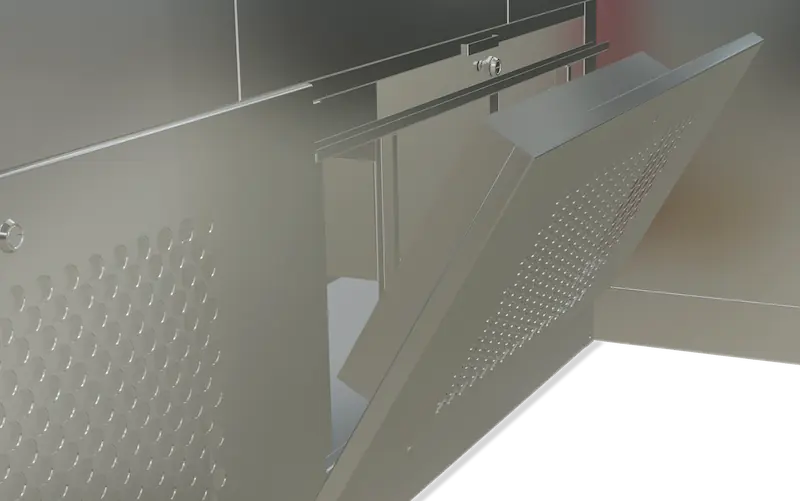

Hassle-free and quick maintenance access for the Pre-Filter replacement

The pre-filter housing cover is designed with the hinges, by swinging down the panel without hassle to remove out the cover panel from the mounting which costs more time to manage during the filter replacement.

Other Features

Filter configuration options to protect the environment and operator.

Filtration stage order:

- G4-Pre-filter

- F8-Fine Dust – Stage 1

- H13-HEPA filter - Stage 2

- H14-HEPA filter downflow air - Stage 3

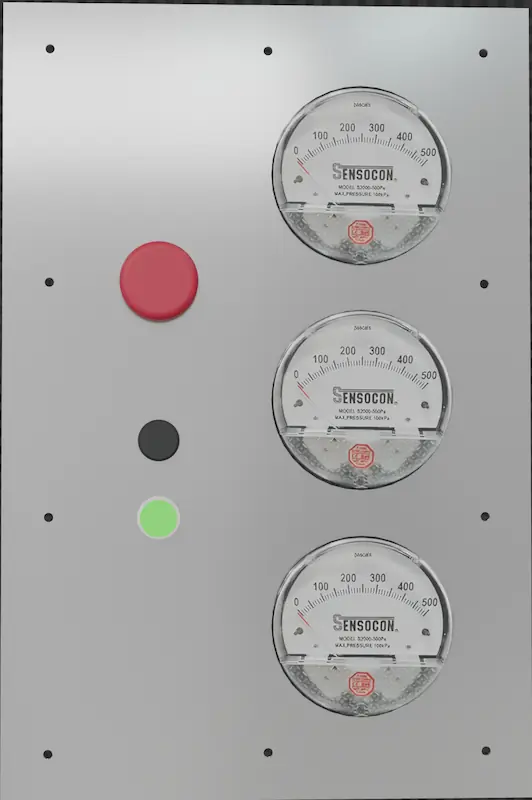

Local operating panel with Smart controller

Its new system allows for simple operating yet assured monitoring. Customization of HMI/PLC Allen-Bradley/Siemens is available.

Principle

- Downflow air is delivered into the Operator’s Breathing Zone (OBZ) via the overhead HEPA filters, thus providing a safe environment for the operator to work.

- Potential dust clouds are suppressed and removed via the exhaust filtration system via the optimized filtration.

- The operator carries out tasks in the high velocity zone at the rear of the Booth so that dangerous dust will not rise into the breathing zone.