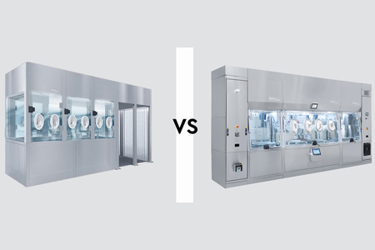

RABS Vs Pharmaceutical Isolators: Which Technology Is Best For An Efficient Contamination Control Strategy?

The publication of the new GMP Annex 1 has redefined the standards for managing aseptic processes, with the primary objective of minimizing contamination risks. This revision reflects the evolution of sterile processes and products, which are becoming increasingly diverse and complex, and the need for pharmaceutical companies to comply with stricter regulatory requirements.

Among the measures recommended to prevent contamination, the use of technologies capable of reducing the human contamination factor is emphasized repeatedly.

Two of the most frequently mentioned technologies in Annex 1 are RABS (Restricted Access Barrier Systems) and Pharmaceutical Isolators, both designed to ensure maximum protection of sterile products.

RABS vs Pharmaceutical Isolators – How to Choose the Right Solution for Your Process Needs?

Restricted Access Barrier Systems: Versatility and Cost-Effectiveness for a Universal Solution.

RABS are barrier systems that physically and aerodynamically separate the sterile process. Operators interact with the products through glove ports and transparent panels, typically made of tempered glass or plastic materials, which act as the physical barrier of the RABS. The aerodynamic barrier is ensured by a unidirectional (laminar) downflow that covers the process area.

RABS can be divided into two categories: Open RABS and Closed RABS.

- Open RABS (O-RABS): Filtered air flows through the sterile process and is then released back into the cleanroom. If equipped with their own ventilation, they are considered “active”; if they rely on the room’s system, they are “passive”.

- Closed RABS (C-RABS): Completely sealed from the external environment, they offer higher protection by recirculating air through an independent ventilation system.

Both types require a Grade B background, with the working area maintained at Grade A under laminar airflow. Cleaning and fumigation activities are often performed manually, which may extend downtime. Moreover, operations rely more heavily on human intervention.

The main advantage of RABS lies in their great versatility and lower cost, making them suitable for integration into many existing processes across a wide range of production settings.

Discover more about our RABS Systems

Pharmaceutical Isolators: Maximum Process Protection.

Pharmaceutical Isolators are fully enclosed barrier systems that, like RABS, use internal laminar airflow to maintain a Grade A environment in terms of particulate levels.

However, unlike C-RABS, Isolators are sealed systems compliant with Class 2 according to ISO 10648-2, making them ideal for maximum containment and process protection. Isolators offer several advantages over RABS: they can be installed in Grade C or D background areas, they feature automated decontamination cycles, they require minimal operator intervention due to a high degree of automation.

Additionally, unlike RABS, Isolators significantly enhance operator safety, especially when handling hazardous products.

These benefits do come at a cost. Isolators are more expensive than RABS—not only due to the complexity of the integrated automation systems, but also because of the additional validation requirements, such as leak testing and decontamination cycle qualification.

Discover more about our Pharmaceutical Isolators Systems

RABS vs Pharmaceutical Isolators: Conclusion.

The choice between RABS and Pharmaceutical Isolators depends on several factors: product type, risk level, company strategy, and available resources.

- RABS remain the more cost-effective and flexible solution, ideal for existing facilities or processes that require adaptability.

- Pharmaceutical Isolators, on the other hand, are the optimal choice for those prioritizing maximum containment, automation, and minimal human risk.

In both cases, the selected technology must be part of a structured contamination control strategy, which is essential for ensuring the quality and safety of sterile products, as defined by GMP Annex 1.

Source: TEMA SINERGIE S.p.A