Reducing Bioburden Risks In Aseptic Manufacturing

By Christian Dunne and Ben Wylie

As market demand for advanced biopharmaceuticals continues to grow so do the demands placed upon modern aseptic processing, and primarily of parenterals such as vaccines. Quality of the final product remains of upmost importance, putting the techniques involved in ensuring sterility during manufacture under the spotlight. The current techniques adopted to ensure this fundamental requirement is met primarily consist of high classification cleanroom areas and barrier/isolator technology, coupled with validated sterilization or decontamination processes to ensure both product and components within the critical areas can be maintained at the required sterility assurance level (SAL).

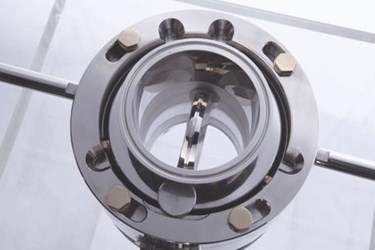

Manufacturers are now benefiting from the introduction of a closed handling method that not only achieves the required SAL along with a reduction or elimination of manual intervention, but also offers the opportunity to reduce the resource associated with cleaning and validating large volume areas, by utilizing a compact and efficient split valve system that is also capable of ensuring a high level of protection while handling potent ingredients that pose a risk to operators.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Pharmaceutical Online? Subscribe today.