Robotic Aseptic Processing For Filling Ready-To-Use (RTU) Vials, Syringes And Cartridges

Fill-finish is the final stage before the product is packaged and administered to the patient. As patient treatments move away from broad population therapies in favor of the targeted treatment of smaller (personalized) patient populations, the biopharmaceutical industry is transitioning to smaller aseptic batch manufacturing processes.

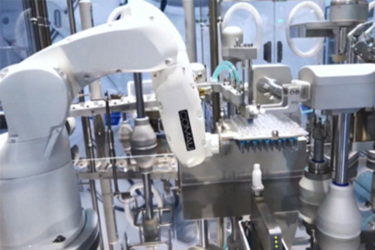

It was not so long ago that robots were focused on end-of-line functions in the pharmaceutical industry, such as case packing and palletizing. Currently, robotic integration is gaining ground in the primary packaging processes for RTU containers, such as vials, syringes and cartridges. In RTU systems, packaging is pre-prepared so that the only step left in the process is to fill and finish the container, which eliminates the majority of process challenges.

Robotic solutions provide pharmaceutical manufacturers with a faster, more flexible and cost-effective way to fill different container formats using the same filling platform, responding to the growing demand for small batches, customized packaging, rapid product and format changeovers along with a less user intervention during the filling process. Conventional systems do not meet the need for small batch flexibility, multiple formats or sizes and repeatable processes that reduces risk.

Advances in technology have made robotics compatible with aseptic manufacturing, with near zero particle generation and complete tolerance to sterilizing agents. Robots offer one particular advantage over traditional aseptic machinery: flexibility. They are completely adaptable and can be reprogrammed with minimal investment if an application or container format changes.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Pharmaceutical Online? Subscribe today.