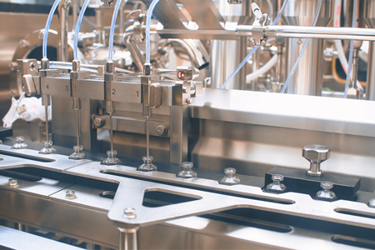

Semi-Automatic Inspection Equipment

Your smart assistant to visual inspection activities

Our semi-automatic PWL Series inspection machines are designed to simply and effectively overcome the challenges associated with manual inspection processes, providing much higher ease-of-use for operators.

The PWL series is designed for simple and effective inspection of vials, ampoules, cartridges and syringes containing injectable liquids, powders or freeze-dried products, handling systems can speed up the inspection for smooth integration into the production line.

Overview

Suitable for following the inspections: particles, cosmetic defects, closure quality, glass surface, neck, bottom, shoulder area, crimping of vials, ampoules tips and more.

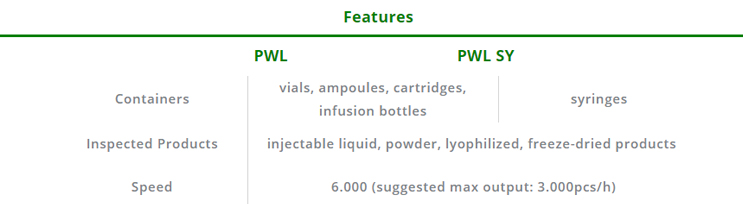

Features

- Compact footprint

- Continuous motion

- Light sources installed from the top, rear, and bottom

- Background filters: black and white polarized filters available to be positioned on the magnifying lens (based on the product to be inspected)

- Separation of defects by categories available

- Change parts optimized for quick changeover

- 21CFR11 - Audit Trail - cGMP and GAMP5

Designed to support your operators

- Operators: one per cabin – dual cabin available back to back

- Magnifying lens

- Inclination of objects: 20°- 30° available

- Reject systems: manual or automatic available

- Working height: 900 ±25 mm

- LED light sources fully adjustable in intensity

- Tyndall light: special light source to make reflecting particles more visible

- Adjustable mirrors installed under and above the containers transport lane

- Control panel: 17” color touchscreen monitor with external keyboard

Syringes configuration

- Syringes are inspected with needle up, this is an advantage to avoid hidden particles under the cap

- Automatic Denester and Renester in-line connection is also available