Solving The Top 3 Pharma Packaging/Manufacturing Issues

By Katie Anderson, Chief Editor, Pharmaceutical Online

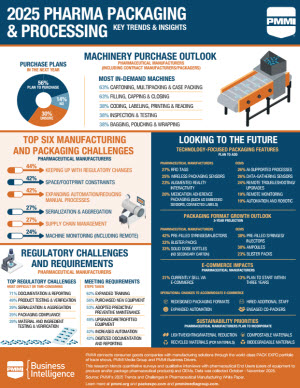

Six key challenges in packaging and manufacturing were identified in a recent study and whitepaper by The Association for Packaging and Processing Technologies (PMMI).

Among them were regulatory changes, space/footprint constraints, expanding automation, serialization/aggregation, supply chain management and machine monitoring. Though we could expand on each of these, regulatory changes, space/footprint constraints and expanding automation garnered more votes than the other challenges. Let’s explore these challenges and see how the industry is tackling them as we move into 2026.

1. Regulatory Challenges

In nearly every conversation I’ve had this year on regulatory issues, the feedback is that close and frequent communication with the regulatory authorities is the key. The FDA took this to heart this year, launching open-door programs designed to improve communication to bring drugs to market faster.

The FDA also launched the Precheck Program, a two-phase solution to getting drugs approved faster. The Facility Readiness Phase opened communication during critical parts in facility design, pre-production, and construction, while the Application Submission Phase aimed to streamline the CMC portion of a drug application.

To prepare staff for regulatory challenges, the PMMI study notes that manufacturers are “expanding employee training, purchasing new equipment, and using predictive/preventive maintenance to ensure compliance.”

In 2025, the FDA also began publishing Complete Response Letters to provide transparency in hopes others could learn from mistakes made. Before you begin beaming with pride with all this open communication, the FDA also announced in 2025 its plan to execute unannounced inspections on foreign manufacturing facilities.

2. Space/Footprint Constraints

There are really only two main ways to solve the issues with space/footprint constraints: design your way into a better-fitting space or design a new one. The pharma industry certainly saw its fair share of facility redesigns, expansions and new builds.

In the past year, AstraZeneca announced plans to expand its facilities in Gaithersburg, Maryland;; Mount Vernon, Indiana and Coppell, Texas, with a plan to build a massive, new drug substance manufacturing facility in Virginia.

AbbVie expanded its Chicago facility to produce more API, and began construction on its Worcester, Massachusetts expansion for more biologics manufacturing.

Lilly announced plans to build a manufacturing sites in Virginia and Texas, as well as plans to expand site capacity in Puerto Rico and India.

These are just a handful of the Greenfield and Brownfield facility plans for 2025 and beyond, but at the heart of these designs is smart facility design to accommodate more flexibility and change.

Modular design is a way facilities can be engineered for flexibility. Not only can the modules be modified to produce different drugs in the same facility, but production can be repurposed from its original intent even if a drug fails in clinicals. The ability to design and manufacture the modules off-site and then install on site also reduces construction time.

3. Expanding Automation

Automation is a major goal for many manufacturers in 2026 and beyond. Not only can it produce drugs more quickly, but it removes operator error and human contamination risks.

Advancements in automation are happening every day in machinery, robotics, quality control, data management and more. For example, four of the finalists just announced for ISPE’s Facility of the Year Awards utilized automation to achieve their advancements. At Johnson & Johnson’s Malvern Protein Lab Expansion, advanced automation was introduced to achieve LEED certification for sustainability and set a new standard for biologics production.

Chugai Pharma incorporated automation strategies and containment solutions into the API manufacturing facility that it completed in 36 months at its Fujeida plant. As a kicker, the company had to also incorporate seismic design to make sure an earthquake didn’t come in and ruin all of its hard work.

Lilly’s Concord facility was designed as a paperless, automated facility with robotics and electronic execution for maximum expediency.

Finally, Bayer’s Solida-1 facility was conceived to change the face of pharma automation with an unprecedented level of end-to-end automation. The modular facility maximized space for its process automation by moving the utilities out, and all the machines communicate with each other to ensure seamless integration. I had the privilege to hear the project’s lead, Jurgen Wiedemann, present on the facility at the recent ISPE Facilities of the Future Conference, so check back in with Pharmaceutical Online for that full account.

A Bright Future

Though regulatory, space constraints and automation certainly have their challenges, pharma manufacturing is tapping into its unending ingenuity to ensure a bright future. Though PMMI’s white paper will be available soon, an infographic (shown above) summarizing its findings is available now.

In addition to the top pharma manufacturing challenges, the infographic also reports on machinery purchase intent, packaging innovation, regulatory challenges and sustainability priorities, among others.