Syringe Forming Lines

Syringes are complex products that require an extremely precise forming process: Stevanato Group syringe manufacturing lines include several specifications, which are normally optional, such as servomotors for controlling the most critical manufacturing phases (cone forming, total length) and flow meters for automatically regulating the burners.

High quality, high reliability

- Cutting-edge, easy-to-use automatic production lines with the aim of maximizing production efficiency, preventing human error and obtaining premium-quality glass containers

- Close ties with the customer throughout every step of the process enable to provide fully custom-made, purpose-built equipment to produce syringes with custom dimensions and shape

- End result guarantees highly reliable and safe critical phases for the pharmaceutical company, thanks to stable and proven processes stemming from extensive experience in design solutions and dimensional control technology

- All the machines operate with the highest mechanical precision and feature easy-to-use HMIs, ensuring seamless high-speed production, fewer rejects, mechanical resistance, and syringes conforming to cosmetic and dimensional standards, to preserve drug integrity

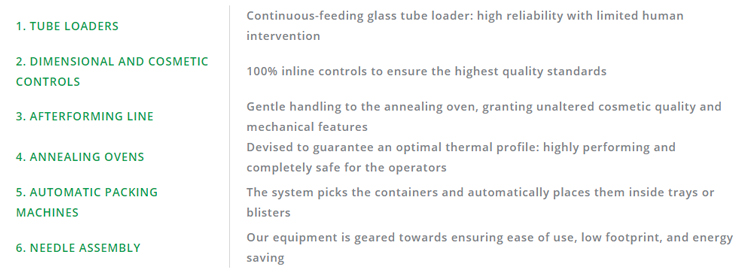

A complete production line or stand-alone modules

Stevanato Group glass converting lines come as a turnkey package, including the forming unit and other process equipment, or as stand-alone modules. Completely automatic washing equipment to remove particles from the glass and reduce cosmetic defects is also available.

Check here the options

Siliconization

Siliconization is a critical parameter that influences the container performance: it must be optimized and monitored to ensure a safe and effective administration to the patient and to guarantee drug quality.

Silicone in the form of emulsions and/or oil is a lubricant that favors and improves the glideability of syringes.

Moreover, the silicone layer minimizes the interactions between the product and the glass container, and prevents certain products from sticking to the internal surface, making the glass appear perfectly transparent.

Optimizing control of the process and its reliability through precise automation, siliconization lines are designed to:

- Increase gliding performance between the glass and the internal components (e.g. rubber parts);

- Improve the flow of liquid solutions inside the container, reducing “dead volume” concerns;

- Reduce the interactions between the pharmaceuticals and the glass containers;

- Process the most common sprayed materials: silicon emulsion or silicon oil.

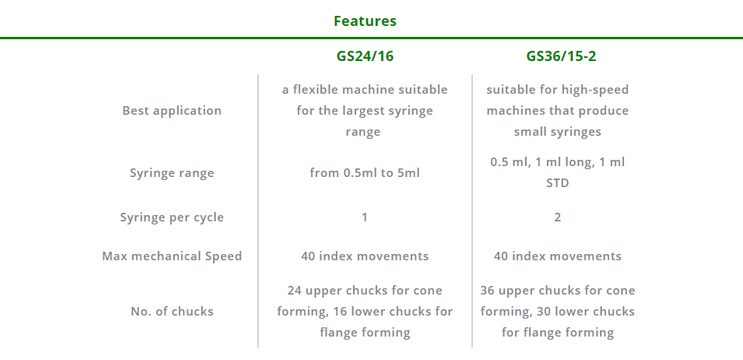

Features

- Pre-heating with electrical heating System;

- Independent delivery system for each spray nozzle;

- Volumetric pumps for silicone dosing accuracy;

- Silicone spray nozzle and air flows to uniformly spread the silicone along the internal surface of the glass product;

- Baking lehr with electrical or gas heating system. The baking lehr can be installed on the siliconization line or be an independent unit, depending on the type of silicone used.