The Human Factor

By Andrew Kit, Director of User Experience, Pall

The business case for single-use systems (SUS) is becoming ever more compelling with the trend towards flexible manufacturing and the need to get products to market faster. At Pall, we see SUS within our business growing year-on-year as more companies make the switch.

Although the switch from conventional stainless steel to SUS has come a long way, in some cases there is still room for improvement in their design. Good product design must incorporate Quality by Design (QbD) – which ultimately ensures the product is of the right quality at the end of its manufacturing process. In a presentation given by GlaxoSmithKline at the 2019 Disposable Solutions for Global Manufacturing event in Amsterdam, it was said that “QbD is key – no integrity test can replace a bad design.”

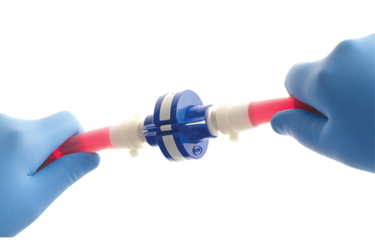

But a technology is only as good as the effectiveness of the person who uses it. One aspect of product design that is often overlooked is ergonomics and ease of use. It has been said that human error is responsible for more than 80 percent of process deviations in the pharmaceutical and related manufacturing environments (1), and biocontainer/bag leakage is still described as one of the top factors limiting the adoption of single-use technology (2). Reports have shown that improving the reliability of SUS and reducing the risk of leakage requires many actions, including improving the training of end-users and the design of the single-use systems.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Pharmaceutical Online? Subscribe today.