ABOUT US

PTI is a leading manufacturer of inspection equipment and a services solutions provider. We specialize in the development of sensory technologies for container closure integrity testing (CCI), package integrity, and seal quality inspection. PTI’s Life Science CCI services provide regulatory guidance and support throughout the pharma product lifecycle. We serve the Life Science industries encompassing Pharmaceutical, Biotech, & Medical Device.

Leading inspection technologies include High Voltage Leak Detection (HVLD), Vacuum & Pressure Decay, Airborne Ultrasound, and Helium leak testing. These innovations find versatile applications across a wide range of packaging formats, including pre-filled syringes, vials, ampoules, cartridges, autoinjectors, IV bags, blister packs, pouches, and numerous other packaging configurations.

PTI’s non-destructive technologies are designed for applications spanning R&D lab testing, automated inspection, and solutions for technology integration.

CONTACT INFORMATION

PTI Packaging and Inspection Systems

8 Skyline Drive

Hawthorne, NY 10532

UNITED STATES

Phone: 914.337.2005

Fax: 914-337-8519

Contact: Michelle Wolf

VIDEOS

-

Testing IV bags in compliance with Annex 1 guidelines requires a robust technology strategy to ensure product quality and patient safety. Learn how to deploy and validate technologies for IV bag CCI.

-

Discover a fully automated CCI inspection system for pre-filled syringes that utilizes a revolutionary deterministic technology, MicroCurrent HVLD.

-

The VeriPac 465 is a deterministic micro leak test system for container closure integrity testing combines technological innovation and practical adjustments to patented dual vacuum transducer technology, PERMA-VAC, to make it the most sensitive and versatile vacuum-based leak detection technology to date.

-

The VeriPac FLEX Systems are available in several configurations to accommodate various package specifications. Each model achieves a specific range of test sensitivity and various test chamber sizes are available depending upon the package size and characteristics.

-

VeriPac 455 is a non-destructive inspection system for highly sensitive micro leak detection of empty & pre-filled syringes, liquid filled & lyophilized vials and other liquid filled packaging. The VeriPac 455 inspection technology that can be incorporated into protocols at any point in the handling process as it is non-destructive, non-invasive and requires no sample preparation.

WEBINARS

-

Learn alternative technology options and data integrity compliance capabilities that are critical to CCIT due to a wide variety of applications and regulatory requirements.

-

In this webinar you'll learn how to assess test method accuracy, information, and data analysis, how to carefully define method transfer objectives for each application, and more.

-

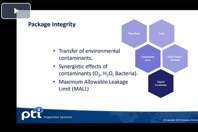

This video discusses the importance of protecting package contents from contaminants, including challenges associated with transport and specifically how altitude and latitude affect packaging formats.

-

This webinar takes a look at the pros and cons of manual visual inspection. Join us in taking a deeper dive into this probabilistic test method.

-

This short podcast focuses on experimental design and statistical tools we use with non-destructive package integrity test systems that produce reliable and robust quantitative test data.

CASE STUDIES

-

A major pharmaceutical entity wanted to ascertain their container system's seal quality. Explore results from a series of leak testing projects that highlighted key issues with their plastic containers.

-

A global pharmaceutical equipment entity was interested to see how various levels of crimping force in vials affect helium leak rate data. Explore the results obtained from this case.

-

A global pharmaceutical entity was comparing vials for helium leak testing services. Explore the results obtained from collecting and tabulating the helium leak rate data as well as the solution.

-

A global pharmaceutical entity was experiencing early package failures from stability studies for a new drug product. Learn about the solution and the results obtained from this case.

-

A nondestructive integrity-testing method will help an implant maker expand its testing program with little effort.

-

Medical device manufacturing is a labor intensive process, requiring operator involvement from manufacturing through final inspection of products. High product costs and superior quality requirements are two reasons for successful integration of airborne ultrasound seal inspection for medical device packaging. By PTI Inspection Systems

-

Ophthalmic products come in a variety of package formats. The liquid-filled packages are often soft containers with snap-on or screw caps, and include foil lidded blister packs for single-use contacts.

WHITE PAPERS

-

Experimental Design And Positive Controls For Package Integrity4/9/2020

Given that the experimental design has only two conditions, leaking and non-leaking, this variable is extremely important to understand. Proper use of positive controls and knowledge of how alternative approaches are applied to challenge a test method support the validity and reliability of the method.

-

Container Closure Integrity Testing: Sensitivity, Automation, Efficiency4/6/2020

Explore the need for sensitive, reliable, and automated container closure integrity testing technologies, and how existing deterministic solutions can help achieve optimum quality assurance goals.

-

Dye Ingress For CCIT: A Poor Bet In A High Stakes Game3/23/2020

The dye ingress test method continues to be a widely used test method for container closure integrity. This paper explains why the dye ingress test method is not a suitable approach.

-

Understanding Ultrasound Technology To Inspect Pouch Seals

Traditional test methods of testing pouch seals are often destructive and can be unreliable. However, ultrasound technology offers a non-destructive means to ensure pouches are airtight.

-

Flexible Insights

As more and more packages and processors convert to flexible packaging from more traditional forms of rigid methods including metal cans, PET and glass bottles or jars, they are confronted with the concern and challenge of how do they insure or equal the seal integrity levels from flexible packaging that they have come to expect from these more traditional packaging methods. Submitted by PTI Inspection Systems

-

How Important Is The Physical Integrity Of The Blister Package?

Untold millions of medicinal tablets and capsules are produced every year, and many of the over-the-counter varieties are encased in blister packs for protection. Existing manual methods for inspecting these packages are subjective and lack repeatability, while electronic techniques have to date been stymied by the great variation in blister packages.

-

Pouch Seal Inspection — Airborne Ultrasound Technology For Better Process And Quality Control

A pouch seal is a structural element that joins flat film material and a component designed to close a pouch airtight. Traditional test methods (e.g. peel strength or burst), can measure the joint strength of the pouch seal using destructive methods that are often unreliable. Submitted by PTI Inspection Systems

-

Understanding Vacuum Decay Leak Testing

The ability to detect leaks is necessary to ensure consistency and integrity of packages. It is also important to detect leaks and defects that are not visibly detectable. VeriPac's non-destructive technology is capable of detecting package leaks and invisible defects using an absolute or differential pressure transducer leak test system. Submitted by PTI - Packaging Technologies & Inspection

-

Deconstructing The Blue Dye Leak Test Method

Blister package manufacturing for tablets and capsules has process and material parameters that are unique to each product. Barrier properties of blister packaging are primarily designed to eliminate moisture ingress, a result of H2O molecules passing through micro leaks over extended periods of time. By Oliver Stauffer, PTI Packaging and Inspection Systems

-

Technology Overview: How To Leak Test Blister Packaging

Most current test methods for blister packages are destructive, time consuming, not sensitive, unreliable, and dependent on the properties of the package lidding material. Small semi-rigid, flexible, and multi-cavity blister packages do not have enough air inside the package to reliably detect defects by simple vacuum decay methods. Submitted by PTI - Packaging Technologies & Inspection

-

Understanding Pressure Decay Leak Testing For Bottles And Containers

Leak detection of empty containers — before the filling and sealing process — is an important step to insure container integrity. Applications in the plastic, blow molding, food, beverage and pharmaceutical industries all require some type of online container integrity system. Submitted by PTI - Packaging Technologies & Inspection

-

Blister Pack Leak Detection: Protecting Product Integrity

The blister packaging process for tablets and capsules is unique to the packaging industry in so many ways. Blister packaging will always exist due to its practicality; but, the things that make blister packaging difficult to work with also make it a desired product presentation. Submitted by PTI Inspection Systems

-

Container And Closure System Integrity Testing In Lieu Of Sterility Testing As A Component Of The Stability Protocol For Sterile Products

The purpose of stability testing is to provide evidence on how the quality of a substance or product varies with time under the influence of a variety of environmental factors such as temperature, humidity, and light, which enables you to establish or modify recommended storage conditions, retest periods, and shelf life or dating period, as the case may be.