An Introduction To Validation Of Aseptic Fill/Finish And Related Processes

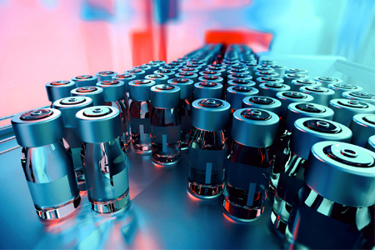

Mesa Labs specializes in providing a comprehensive range of monitoring solutions for the decontamination and sterilization processes critical to aseptic filling in the pharmaceutical, food, and beverage industries. Their products and services ensure sterility throughout aseptic workflows, including process fluid distribution, Water for Injection (WFI), API filling, and sterilization of product packaging and equipment components.

Mesa offers advanced solutions for equipment, environment, and product validation, working synergistically to ensure product safety and regulatory compliance. Their robust portfolio includes biological indicators and other tools designed to validate even the most challenging sterilization scenarios, such as piping installations and cleanroom environments, including isolators, RABS, and filling rooms.

The company's technical expertise spans over 35 years, offering consultative services and contract studies like bioburden and D-value assessments. Mesa’s products meet stringent standards, including USP and ISO regulations, and are manufactured in an FDA-registered facility certified to ISO 13485:2016.

Mesa’s innovative tools help eliminate validation cycle failures, reduce production downtimes, and prevent costly errors. By ensuring consistent placement of indicators and using state-of-the-art monitoring solutions, manufacturers can achieve efficient, reliable sterilization processes. Their solutions support manufacturers in overcoming sterilization challenges, enhancing safety, and maintaining sterility to protect end-users.

With a strong commitment to quality and innovation, Mesa Labs positions itself as a trusted partner in aseptic process validation and sterilization monitoring, ensuring the safety and efficacy of critical products.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Pharmaceutical Online? Subscribe today.