Finding An Optimal Harvest Solution By Considering Both Cost And Sustainability

By Levi M. Larsen, Economic Analyst; Jon Kruger, Engineer II, Systems Design; Kayla J. Spivey, Content Specialist III

Finding an optimal harvest solution that balances cost and sustainability is crucial in today's biomanufacturing landscape. This white paper, focused on the DynaSpin Single-use Centrifuge, explores how single-use technologies can provide an efficient, cost-effective, and sustainable alternative to traditional depth filtration methods. As bioproduction scales increase, the need for high-performance harvest solutions becomes paramount. Manufacturers must decide between various technologies to efficiently separate valuable products from cell debris and particulates post-bioreactor.

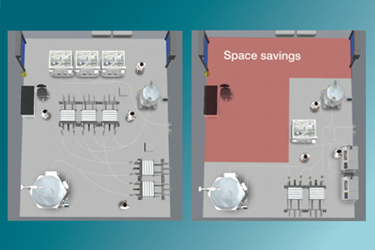

Traditionally, stainless steel centrifuges, requiring rigorous cleaning and validation processes, were the norm. However, the emergence of single-use technologies like depth filtration and single-use centrifuges offers more flexible and scalable options. This paper evaluates these technologies, comparing their performance, cost implications, and environmental impact. Single-use centrifugation, represented by the DynaSpin system, demonstrates significant advantages in reducing consumables, automation, and overall operational efficiency. By assessing these factors, we aim to guide biomanufacturers toward more sustainable and cost-effective harvest solutions, ensuring optimal productivity and compliance in large-scale bioproduction.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Pharmaceutical Online? Subscribe today.