Five Advancements In Tablet Compression That Pharma Can't Ignore In 2026

By Tony Beal, Natoli Engineering

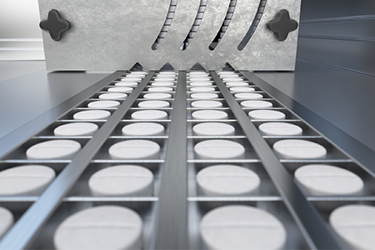

The escalating demand for efficient and consistent tablet production, alongside increasingly complex formulations, is driving essential innovations in tablet compression tooling. These advancements extend beyond simple material strength; they fundamentally improve speed, product quality, and operational flexibility on the manufacturing floor.

Manufacturers can achieve greater output and minimize downtime by adopting smarter tooling materials—like modern coatings and advanced steel blends—that enhance durability and resist sticking. This longevity is complemented by press automation, which utilizes real-time monitoring and predictive maintenance to ensure consistent operation and preempt unexpected failures. To boost production from existing footprints, multi-tip and modular tooling designs allow for higher throughput and rapid changeovers. Furthermore, in-press quality control with machine vision and automated checks ensures immediate batch integrity. Finally, leveraging digital simulation and compaction data early in the design process reduces trial and error, speeding up successful scale-up.

Understanding these five critical advancements will enable engineering teams to drive operational excellence and reliably deliver safe, effective medication to patients.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Pharmaceutical Online? Subscribe today.