High Speed In-Line High Voltage Leak Detection (HVLD) For Pre-Filled Syringes

HVLD is High Voltage Leak Detection, a sensitive, non-destructive technology to test container closure integrity in a variety of liquid-filled pharmaceutical and medical containers including glass vials and ampoules, IV-bags, Blow Fill Seal (BFS) bottles and cards and pre-filled syringes. HVLD can be used to conduct CCIT on any liquid-filled product as long as the container is made of electrically insulated material and it contains an electrically conductive solution.

Features:

- High-Speed HVLD for Prefilled Syringes

- Needle Shield and Stopper inspection capability.

- 4+ Inspection Stations

- Syringe sizes 1ml, 2ml, 5ml

- Inspection speeds of 20 to 600pcs/minute

There are a variety of methods widely used within the pharmaceutical and food industries for the detection of pinholes, cracks, and defective seals in various pharmaceutical and food packaging. These tests range from vacuum or pressure decay tests, to submerging the entire container into a dye solution under pressure and visually inspecting the container for the presence of dye, or more advanced vision systems to inspect for certain defects in the container. Nikka Densok’s High Voltage Leak Detection systems are USP 1207 compliant.

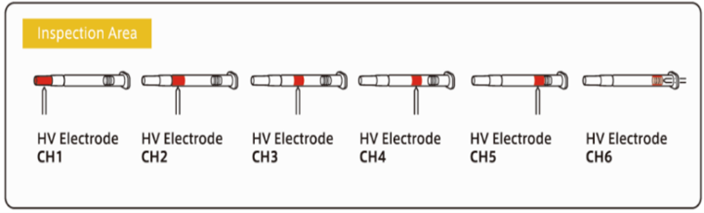

During HVLD, product containers are scanned with electrode probes of various types. Containers used can be glass, plastic or poly-laminates. To be tested, the product or container typically needs to be approximately 30% full of liquid.

A high-frequency voltage potential, or spark, is applied to the container, and the current volume is measured. The current seeks path of least resistance to the container.

If a container is defective, the resulting resistance differential and change in current flow through the liquid in the container will indicate the presence of container seal defects, pinholes, leaks, or cracks.

A defective container will have a larger electric current volume than a container with no leaks.

Nikka Densok’s HVLD pinhole detection systems can be customized to meet a variety of project needs. The HVLD systems can process product containers made of electrically insulated materials such as glass, rubber, plastic, or plastic film at production speeds.

Where applicable, Nikka Densok’s pinhole detection systems feature multiple, high-voltage stations; a variety of product posture conditions to ensure inspection of entire containers; the latest, enhanced electronics and built-in safety features to eliminate product breakage.