Intuitive Bioprocess Scale-Up From Bench Scale To Pilot Scale

Scaling up bioprocesses from bench to pilot scale is often fraught with challenges. Maintaining consistent growth kinetics, productivity, cell health, and efficient mass transfer are critical for a successful transition. Effective control strategies for key parameters such as agitation, dissolved oxygen (DO), carbon dioxide (CO2), and nutrient supplementation are essential to ensure optimal cell performance and product yield as you increase volume.

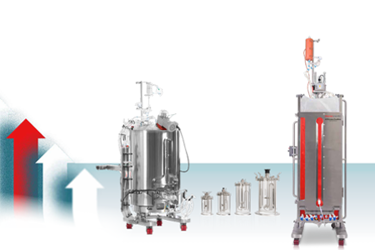

This application note presents a comparative study of the Thermo Scientific™ HyPerforma™ and DynaDrive™ Single-Use Bioreactors (S.U.B.s) at the 50 L and 500 L scales. It details the process control parameters used for a high-demand fed-batch culture of IgG-producing CHO-K1 cells, including agitation, dissolved oxygen, pH, and nutrient supplementation. The study demonstrates the ability of both the HyPerforma and DynaDrive S.U.B.s to maintain stable growth kinetics, robust cell viability, and consistent protein titers across different scales.

Explore how the innovative design of the DynaDrive S.U.B., with its laser-drilled hole sparger and multi-impeller system, facilitates efficient mass transfer and gas control, leading to highly scalable performance. Access the full application note for in-depth insights and data.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Pharmaceutical Online? Subscribe today.