Line Optimizer: Reliably Configuring And Controlling Production Lines

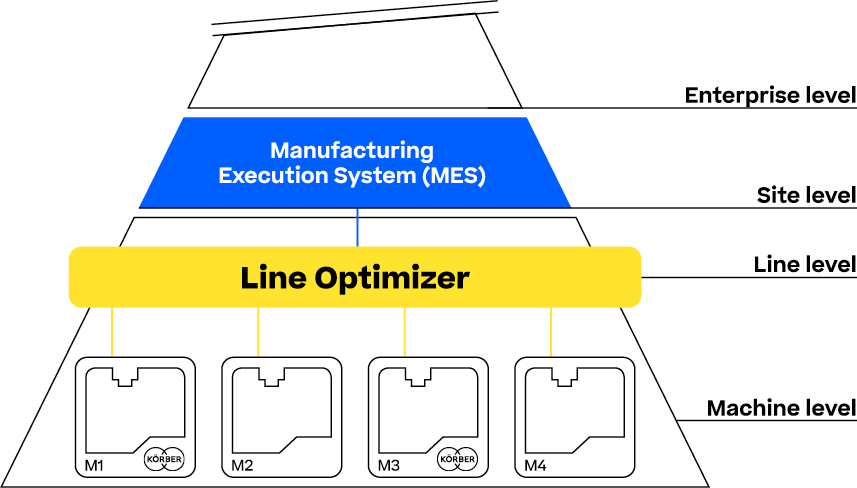

Smooth connectivity between your machines and to other systems is a precondition for reliable and secure pharmaceutical production. With the Line Optimizer from Körber enables you to set standards, shape, and control quality-related processes, and optimize the effectiveness of your production line.

Configure and control your machines or your entire pharmaceutical production line via a single centralized solution — Line Optimizer from Körber. Körber provides you with a standard interface for your machines and components. You can use it for complete production locations or throughout the entire company. This makes operations efficient and ensures the seamless integration of your production-related systems. We help you boost your product quality and reduce the cost and effort associated with new implementations, conversions, and maintenance.

Line Optimizer can be adapted to a wide range of different pharmaceutical production lines, from filling and packaging to use in biotechnology facilities. You determine the scope of functions it provides and create a solution that is perfectly adapted to your needs. To do this, you select the functions you need from two main applications: Manage and Execute.

The various modules are freely configurable. Regulatory-mandated line reconfigurations or format changes are carried out efficiently and flawlessly thanks to guided processes, with augmented reality also available as an option. Line Optimizer easily enables you to handle future implementations, such as the introduction of new pharmaceutical production software, at individual locations or throughout the company without problems.

Scalable for every use case

Line Optimizer - Manage

Line Optimizer - Manage

A line management system to harmonize machine interfaces. providing a visualization solution to allow the operator to manage the entire line from a centralized location. All batches can be controlled and monitored. After batch completion, a consolidated report can be generated through this function.

Line Optimizer - Execute

Designed for customers to support operators with guided workflows, the module Execute is ready for use on any browser-compatible device or as augmented reality using Microsoft Hololens© 2. This function set enables seamless digital documentation of all process steps.

Benefits

Standard interfaces

Supports data integrity between your systems, thanks to coordinated machine interfaces based on the latest industry standards

Efficient processes

Reduces the cost and effort needed for the implementation and maintenance of your lines

Better quality

Increases your product quality by means of digital step-by-step instructions and automated documentation

Device independency

Device independency through browser-based system, tablets, smartphones, Realware, and Microsoft Hololens.

Operator enablement

Fast system introduction and enablement for new machine operators through unitary operation of an entire line and the use of augmented reality

Monitoring

Simple and structured overview of all relevant line parameters (such as OEE) as well as machines and associated alarms