KOERBER PHARMA

With over 125 years of in-depth pharma technology expertise, we truly understand the process and regulation challenges you face day to day, from the beginning to the end of your production. This is why we offer a unique portfolio of integrated solutions, spanning consulting, inspection, handling, packaging machines and materials, track & trace, and software, giving you everything you need to unlock the potential of your productivity and your business.

In an industry that has to adhere to stringent safety and regulatory standards, and is reliant on the optimization of production, you are looking for someone to deliver, and that is what we do. As your personal partner, as a system integrator, a service provider, and a product vendor, with our dedicated people, our global footprint, our decades of software and hardware expertise in pharma, we deliver on safety, we deliver on productivity, we deliver on the promises we make. We deliver the difference your business needs.

FEATURED ARTICLES

-

Connect shopfloor equipment with enterprise systems to streamline your data flow. Learn how automation standards enhance integration and see a live demonstration of unified line performance in action.

-

Discover how manual precision at scale bridges packaging gaps, accelerates product launches, and ensures uninterrupted supply to deliver quality when automated equipment isn’t yet operational.

-

VHP biodecontamination ensures aseptic manufacturing, but BI variability challenges validation. Addressing rogue BIs and regulatory shifts strengthens contamination control and process reliability.

-

Explore how AI is transforming visual inspection and gain a deep understanding of defect detection, real-time performance, and integration challenges.

-

Explore a modular approach to Pharma 4.0 that empowers organizations to embrace digital transformation at their own pace and is tailored to their unique needs.

-

Uncover how end-to-end digital twins and Integrated Process Models are transforming manufacturing to enhance flexibility, accelerate time-to-market, and enable real-time decision-making.

-

Explore how eValidation revolutionizes the pharmaceutical industry by enhancing compliance, efficiency, and data integrity, as well as its indispensable role in modernizing traditional validation methods.

-

Asian pharma manufacturers are constantly under pressure to produce high quality products on time. Explore how Asian pharmaceutical companies are leveraging MES to enhance efficiency and compliance.

-

Discover why digitization is crucial for cell and gene contract manufacturers by learning the various benefits digital transformation can offer such as efficiency, compliance, and innovation.

-

Ensure product quality and patient safety by examining the FDA's draft guideline on Computer Software Assurance that emphasizes a risk-based approach to streamline software validation.

-

Biomass soft sensors utilize existing measurements from hard sensors to predict biomass levels in real-time. Explore how to enhance your bioprocessing production, decision-making, and efficiency.

-

The industry is shifting to cloud-based Manufacturing Execution Systems (MES). Discover how you can use a modern MES to enhance efficiency, collaboration, and compliance.

-

The industry is on the verge of a digital revolution. Find out how to navigate the digital revolution with a digital maturity assessment to guide digital transformation, efficiency, and sustainability.

-

Discover how to enhance your pharmaceutical production efficiency with an intelligent MBR design that offers tailored software, handling systems, and inspection machines.

-

Contamination Control Strategies (CCS) have long been a main concept, but advancing requirements and regulatory expectations create a challenge. Learn how to be effective and compliant with your CCS.

-

Learn how a leading CDMO partnered with Körber to quickly deploy a high-speed packaging solution to meet tight production deadlines in the face of a global pandemic.

-

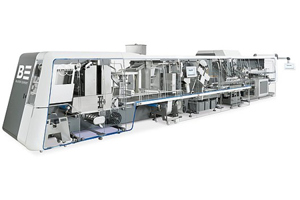

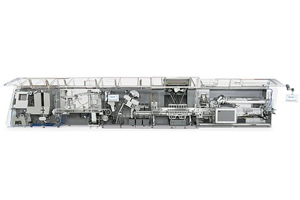

In the pharmaceutical industry, processes are subject to continuous change due to evolving requirements and regulations. Consequently, pharmaceutical companies and contract packagers often require adaptable packaging solutions, such as blister machines, to meet these dynamic needs.

-

How can the performance of a production line be improved while minimizing downtime? One effective approach is to use accumulators between upstream and downstream machines.

-

AI-supported inspection processes offer a future-proof solution to the challenges of vision inspection. Learn how to get started with AI-supported inspection.

-

Containment is growing in importance due to increasingly stringent legal requirements for packaging solid medicines. Learn in detail about containment solutions for the pharmaceutical industry.