Pharmaceutical Rotary Tablet Press: NP-255

Setting a New Benchmark for Ease of Operation

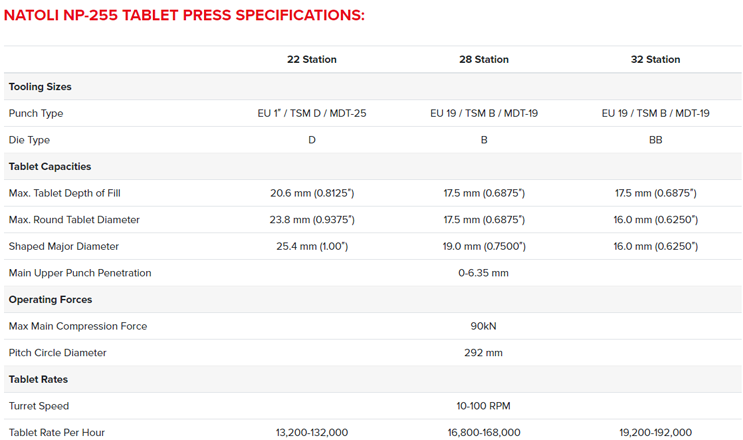

The NP-255 is a robust tablet press that was built to meet even the most demanding needs of the mid-sized tableting industry. The press has features and options designed to increase production, improve tablet quality, reduce waste, and set a new benchmark for ease of operation. Designed, engineered, and manufactured in the USA, this unique machine has a maximum production speed of 192,000 tablets per hour.

With a hardened steel die table, a gravity feeder that is interchangeable with a two-paddle forced feeder, and our industry-leading intuitive Natoli AIM™ ProPluscontrol system, the NP-255 is the new standard for value in the mid-sized tableting industry.

Key Benefits:

- The NP-255 boasts features essential for successful mid-sized tableting without the full-scale price. Ready to take on your manufacturing needs, the NP-255 is easy to operate and utilizes Natoli AIM™ ProPlus Control System. Proudly designed, engineered, and manufactured in the USA, the NP-255 is the new standard for value in the mid-sized tableting industry.

- AUTO-LUBRICATED PUNCH GUIDES – Reduce wear and heat build-up, minimizing sticking and binding.

- EASY ACCESS TO DOSING, COMPRESSION & OVERLOAD SETTINGS – Allows press operators to adjust settings while press is in production.

- Push-button, Self-adjusting Lower Punch Retainers shorten installation time and reduce tooling and cam wear.

Press Features

- Standard TSM and EU B, D, or BB tooling

- Intuitive AIM™ control system provides operation feedback to help maintain tablet quality and improve productivity

- Continuously lubricated punches, cams, and turret to help eliminate wear, reduce heat, and minimize product sticking issues

- Tablet weight, thickness, and hardness adjustments can be made as needed during production

- Completely segregated compression and mechanical zones

- Punch barrels and die table are vacuumed during production to eliminate build up and reduce change over time

- Upper and lower punch guides have soft seals to reduce punch binding and heat in the punches, and contain the product granulation

- Reduced product loss with our specially designed feeder and powder recirculation system

- Upper and lower cam track guards keep cams cleaner to reduce heat, wear, and increased tooling life

- Lower punch retainers to help maintain consistent tablet weight

- Direct drive gears for decreased wear and slippage

- Turret mounted with upper and lower tapered bearing

- cGMP- and CE-compliant

Optional Features

- Instrumented force monitoring

- Combination caster/levelers for easy mobility and setup

- Dual-paddle power rotary forced feeder

- Tablet reject chute

- 3VT System

- Hopper vibration unit