Production-Scale Pharmaceutical Filling Systems

Dec‘s philosophy is to develop customer-specific modules and equipment. Starting with agreed project scope, intensive brainstorm sessions, strong design processes and (customer) reviews, the aim is to deliver an innovative filling solution. During the concept development, risk analysis is an important tool in the decision-making process.

Frequent and intense discussions with the production site team (Q&A, R&D, Process development) and expert engineers are necessary to make the right decisions to achieve the best result. In the Fill-Finish pharmaceutical industry, several technology solutions are in high demand. There is no fit-for-all solution; each production project is unique.

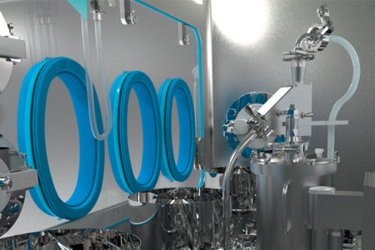

The equipment filling solutions and modules need to be cGMP compliant, dependable and accurately designed to comply with the most recent revisions of the "Annex 1 Manufacture of Sterile Medicinal Products guidelines". Moreover, all filling equipment and modules need to be configured for seamless integration into any production line and designed to accommodate various speeds and containers, including RTU / RTF (Ready To Use or Ready To Fill) bottles, vials, cartridges, syringes and pre-sterile nested trays.