20% Solid Suspension Achieved With Ultra Sanitary In-Line Mixer

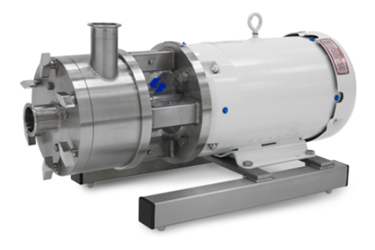

A global manufacturer of medical materials focused on medical aesthetics and neurotoxin therapy wanted to create a 20% solid suspension of a calcium product in water with a particle size of 10 microns. This was to be done in batches of approximately 55 US gallons in the manufacture of an artificial bone implant slurry. The customer’s main aim was to reduce particle size and to speed up their processing time by achieving the desired particle size reduction in a single pass. They had already had success using sonification for this process but wanted to replicate the desired results with a Silverson mixer. See how a Silverson mixer yielded the desired results in a faster processing time.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Pharmaceutical Online? Subscribe today.